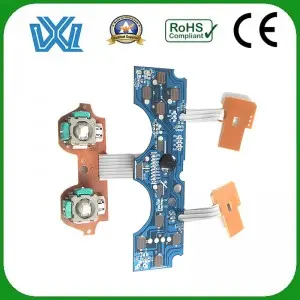

Lub PCB (Printed Circuit Board) yog lub hauv paus ntawm cov khoom siv hluav taws xob, tso cai rau kev sib txuas thiab kev khiav ntawm hluav taws xob ntawm ntau yam khoom.Txawm hais tias koj yog tus nyiam siv hluav taws xob lossis tus kws tshaj lij, paub yuav ua li cas los tsim PCB circuits yog qhov kev txawj ntse tseem ceeb uas tuaj yeem txhim kho koj cov haujlwm tech.Hauv qhov blog no, peb yuav muab cov lus qhia ib kauj ruam los ntawm kauj ruam yuav ua li cas thiaj ua rau PCB Circuit Court.

1. Tsim thiab schematic creation:

Thawj kauj ruam hauv kev ua PCB Circuit Court yog tsim thiab tsim cov schematic.Siv cov software tsim schematic, xws li Eagle lossis KiCad, kos daim duab kos duab.Ua tib zoo tso rau ntawm cov khoom, ib qho kev pom zoo uas ua kom lub logic ntws ntawm cov teeb liab thiab kev ua haujlwm tau zoo yog qhov tseem ceeb.

2. PCB layout:

Thaum cov schematic ua tiav, cov kauj ruam tom ntej yog los tsim cov txheej txheem PCB.Cov txheej txheem no suav nrog kev hloov cov khoom sib txuas thiab kev sib txuas los ntawm schematic mus rau lub rooj tsav xwm lub cev tsim.Muab cov khoom sib xyaw nrog lawv cov pob khoom, ua kom muaj kev taw qhia kom raug thiab tswj xyuas qhov sib txawv kom tsis txhob cuam tshuam.

3. Phaj etching:

Thaum lub PCB layout tiav, nws yog lub sij hawm los etch lub rooj tsavxwm.Ua ntej luam lub rooj tsav xwm hauv Circuit Court rau hauv daim ntawv tshwj xeeb uas siv lub tshuab luam ntawv laser.Muab cov ntawv luam tawm rau ntawm tooj liab clad PCB thiab ua kom sov nrog cov hlau lossis laminator.Lub tshav kub hloov tus cwj mem los ntawm daim ntawv mus rau lub rooj tsavxwm, tsim ib txheej tiv thaiv ntawm cov kab tooj liab.

4. Etching txheej txheem:

Thaum qhov kev hloov pauv tiav, nws yog lub sijhawm los etch lub rooj tsavxwm.Npaj ib lub thawv nrog cov tshuaj etching uas tsim nyog (xws li ferric chloride) thiab poob rau hauv lub rooj tsavxwm.Maj mam agitate qhov kev daws teeb meem kom tshem tawm cov tooj liab ntau dhau ntawm qhov chaw tsis muaj kev tiv thaiv, tawm hauv cov kab uas xav tau xwb.Thaum lub sij hawm tus txheej txheem no, nco ntsoov ua raws li kev tiv thaiv kev nyab xeeb xws li hnav hnab looj tes thiab tsom iav, vim tias cov tshuaj etching tuaj yeem ua rau muaj kev phom sij.

5. Drilling:

Tom qab etching, qhov yuav tsum tau drilled rau qhov chaw.Siv ib lub laum nrog me ntsis zoo uas phim qhov loj ntawm cov khoom coj.Ua tib zoo xyaum los ntawm cov ntsiab lus tsim nyog thiab xyuas kom meej tias cov qhov tau huv si thiab tsis muaj cov khib nyiab.

6. Vuam:

Tom qab lub rooj tsavxwm tau etched thiab qhov drilled, nws yog lub sij hawm los solder lub Cheebtsam mus rau lub PCB.Pib los ntawm threading lub Cheebtsam los ntawm lawv cov qhov, xyuas kom meej tias lawv tau ruaj ntseg zaum.Tig lub rooj tsavxwm thiab solder txhua yam, thov cov cua sov kom yaj cov hlau solder thiab tsim ib daim ntawv cog lus muaj zog.Siv cov hlau soldering zoo thiab flux kom ua tiav huv, txhim khu kev qha cov pob qij txha.

7. Test:

Tom qab soldering tag nrho cov Cheebtsam, lub functionality ntawm lub Circuit Court yuav tsum tau kuaj.Siv ib lub multimeter los xyuas cov kab txuas txuas ntxiv thiab xyuas cov kev sib txuas kom raug.Tsis tas li ntawd, ua qhov kev tshuaj ntsuam xyuas kom paub tseeb tias tsis muaj cov txuas txuas txuas lossis cov pob qij txha.

nyob rau hauv xaus:

Tsim PCB circuits yuav zoo li daunting thaum xub thawj, tab sis nrog cov kev paub zoo thiab cov cuab yeej, nws tuaj yeem dhau los ua txoj haujlwm ua tiav.Los ntawm kev ua raws li cov lus qhia ib kauj ruam dhau los uas tau muab rau hauv qhov blog no, koj tuaj yeem ntseeg siab ua PCB circuits rau koj cov phiaj xwm hluav taws xob.Nco ntsoov, kev xyaum ua kom zoo tag nrho, yog li tsis txhob poob siab yog tias nws yuav siv sij hawm ob peb zaug kom tau txais txoj kev dai.Nrog rau lub sijhawm thiab kev paub dhau los, koj yuav muaj peev xwm ua tiav cov txheej txheem thiab kev ua haujlwm siab PCB.

Lub sij hawm xa tuaj: Plaub Hlis-07-2023