PCB (Printed Circuit Board) ke motheo oa lisebelisoa tsa elektroniki, tse lumellang likhokahano le phallo ea motlakase lipakeng tsa likarolo tse fapaneng.Hore na o setsebi sa ho itlosa bolutu ka elektroniki kapa setsebi, ho tseba ho etsa lipotoloho tsa PCB ke litsebo tsa bohlokoa tse ka ntlafatsang merero ea hau ea theknoloji.Ho blog ena, re tla fana ka tataiso ea mohato ka mohato mabapi le mokhoa oa ho etsa potoloho ea PCB.

1. Moralo le meralo ea moralo:

Mohato oa pele oa ho etsa potoloho ea PCB ke ho rala le ho theha moralo.U sebelisa software ea moralo oa moralo, joalo ka Eagle kapa KiCad, taka setšoantšo sa potoloho.Ho beha likarolo ka hloko, moralo o nepahetseng o netefatsang phallo ea mats'oao le ho tsamaisa hantle ho bohlokoa.

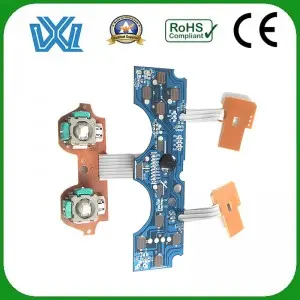

2. Sebopeho sa PCB:

Hang ha moralo o phethiloe, mohato o latelang ke ho theha sebopeho sa PCB.Ts'ebetso ena e kenyelletsa ho fetisetsa likarolo le likhokahano ho tloha ho schematic ho ea ho moralo oa boto ea 'mele.Hlophisa likarolo le liphutheloana tsa tsona, ho netefatsa maemo a nepahetseng le ho boloka sebaka se lekaneng ho qoba tšitiso.

3. Ho fata poleiti:

Hang ha sebopeho sa PCB se phethiloe, ke nako ea ho etch boto.Qala ka ho hatisa moralo oa boto ea potoloho pampiring e khethehileng ea phetisetso u sebelisa printa ea laser.Beha khatiso ho PCB e apereng koporo 'me ue chese ka tšepe kapa laminator.Mocheso o fetisetsa enke ho tloha pampiring ho ea boto, ho etsa lera le sireletsang litseleng tsa koporo.

4. Ts'ebetso ea etching:

Hang ha phetisetso e felile, ke nako ea ho etch board.Lokisetsa setshelo se nang le tharollo e loketseng ea etching (joalo ka ferric chloride) ebe u qoelisa boto ho eona.Ka bonolo sisinya tharollo ea ho tlosa koporo e feteletseng ho tloha libakeng tse sa sireletsoeng, ho siea feela litsela tse lakatsehang.Nakong ea ts'ebetso ena, etsa bonnete ba hore u nka mehato ea tšireletso e kang ho roala liatlana le likhalase, kaha tharollo ea etching e ka ba kotsi.

5. Ho cheka:

Ka mor'a etching, masoba lokela ho phunngoa ho beha likarolo.Sebelisa boro e nang le sekotoana se setle se ts'oanang le boholo ba likarolo tsa lead.Hlakola ka hloko lintlheng tse behiloeng 'me u netefatse hore masoba a hloekile ebile ha a na litšila.

6. Welding:

Ka mor'a hore boto e etched le masoba cheka, ke nako ea ho solder likarolo holim'a PCB.Qala ka ho kenya likarolo ka har'a masoba a tsona, ho etsa bonnete ba hore li lutse ka mokhoa o sireletsehileng.Fetola boto 'me u solder karolo ka 'ngoe, u sebelise mocheso ho qhibilihisa terata ea solder le ho theha maqhama a matla.Sebelisa tšepe ea boleng bo holimo le flux ho fihlela manonyeletso a hloekileng, a tšepahalang a solder.

7. Teko:

Kamora ho kopanya likarolo tsohle, ts'ebetso ea potoloho e tlameha ho lekoa.Sebelisa multimeter ho lekola ts'ebetso ea morao-rao le ho netefatsa likhokahano tse nepahetseng.Hape, etsa tlhahlobo ea pono ho netefatsa hore ha ho na marokho a solder kapa manonyeletso a batang.

ha re phethela:

Ho theha lipotoloho tsa PCB ho ka bonahala ho le boima qalong, empa ka tsebo le lisebelisoa tse nepahetseng, e ka fetoha mosebetsi o ka finyelloang.Ka ho latela tataiso ea mohato ka mohato e fanoeng blogeng ena, o ka etsa lipotoloho tsa PCB ka kholiseho bakeng sa merero ea hau ea elektroniki.Hopola, boikoetliso bo etsa hore e be e phethahetseng, kahoo u se ke ua nyahama haeba ho nka mehato e seng mekae ho fumana nako ea ts'ebetso.Ka nako le boiphihlelo, o tla khona ho theha lipotoloho tse rarahaneng le tse sebetsang hantle tsa PCB.

Nako ea poso: Jul-07-2023