Hoos ilaa sare u kala soocida waa sidatan:

94HB/94VO/22F/CEM-1/CEM-3/FR-4

Faahfaahinta waa sida soo socota:

94HB: kartoonka caadiga ah, oo aan dabci karin (walaxda ugu hooseeysa, feerka dhinta, looma isticmaali karo guddi koronto ahaan)

94V0: kartoonnada ololka celinaya ( feeray dhiman )

22F: loox fiber galaas badhkiis ah oo hal dhinac ah ( feeray dhinta)

CEM-1: looxa fiberglass ah oo hal dhinac ah (waa in lagu qodaa kombuyuutar, oo aan la feerayn)

CEM-3: Guddi laba-geesood ah oo laba-geesood ah (marka laga reebo kartoonada laba-geesoodka ah, taas oo ah qalabka ugu hooseeya ee muraayadaha laba-geesoodka ah. Qaybaha fudud ee laba-geesoodka ah ayaa isticmaali kara alaabtan, taas oo ah 5 ~ 10 yuan / square mitir ka jaban FR-4)

FR-4: Looxa fiberglass laba-dhinac ah

Jawaabta ugu fiican

1.c Kala soocida guryaha dib u ololka waxa loo qaybin karaa afar nooc: 94V—0/V-1/V-2 iyo 94-HB

2. Diyaarinta: 1080=0.0712mm, 2116=0.1143mm, 7628=0.1778mm

3. FR4 CEM-3 waa looxa, fr4 waa looxa fiber galaas, cem3 waa substrate isku dhafan

4. Halogen-free waxa loola jeedaa maadada aasaasiga ah ee aan ku jirin halogen (fluorine, bromine, iodine iyo xubno kale), sababtoo ah bromine waxay soo saari doontaa gaas sun ah marka la gubo, taas oo looga baahan yahay ilaalinta deegaanka.

Shan.Tg waa heerkulka kala-guurka dhalada, taas oo ah, barta dhalaalka.

Guddiga wareeggu waa inuu noqdaa mid u adkaysta ololka, ma guban karo heerkul gaar ah, kaliya wuu jilicsan karaa.Barta heerkulka wakhtigan waxa loo yaqaan heerkulka kala-guurka dhalada (Tg point), qiimahani waxa uu la xidhiidha xasiloonida cabbirka guddiga PCB.

Waa maxay guddiga sare ee Tg PCB iyo faa'iidooyinka isticmaalka Tg PCB sare

Marka heerkulka sare ee looxyada daabacan ee Tg ay kor u kacaan meel gaar ah, substrate-ku wuxuu ka bedeli doonaa "xaalad galaas ah" oo loo beddelo "xaalad caag ah", heerkulka wakhtigan waxaa loo yaqaannaa heerkulka kala-guurka muraayadda (Tg) ee looxa.Taasi waa, Tg waa heerkulka ugu sarreeya (° C.) kaas oo substrate-ku uu yahay mid adag.Taasi waa in la yidhaahdo, qalabka caadiga ah ee PCB ma aha oo kaliya inay jilciyaan, qaabeeyaan, dhalaalaan, iwm heerkulka sare, laakiin sidoo kale waxay muujinayaan hoos u dhac weyn oo ku yimaada qalabka farsamada iyo korantada (Waxaan u maleynayaa inaadan rabin inaad aragto xaaladdan alaabtaada. adoo eegaya kala soocida looxyada PCB.).Fadlan ha koobiyn waxa ku jira boggan

Guud ahaan, Tg saxanku waxa uu ka sarreeyaa 130 darajo, Tg sare ayaa guud ahaan ka weyn 170 darajo, Tg dhexdhexaad ah ayaa ka weyn 150 darajo.

Guud ahaan, looxyada PCB ee daabacan ee leh Tg ≥ 170°C waxa loo yaqaan sabuuradaha daabacan ee sare ee Tg.

Tg ee substrate-ka waa la kordhiyaa, caabbinta kulaylka, caabbinta qoyaanka, caabbinta kiimikada, iyo xasilloonida guddiga daabacan ayaa la wanaajin doonaa oo la hagaajin doonaa.Qiimaha sare ee TG, ayaa si fiican u caabbinta heerkulka guddiga, gaar ahaan habka-free-lead, waxaa jira codsiyo badan oo Tg ah.

Sare Tg macnaheedu waa iska caabbinta kulaylka sare.Iyada oo horumarka degdega ah ee warshadaha elektiroonigga ah, gaar ahaan alaabada elektiroonigga ah ee ay matalaan kombuyuutarrada, ayaa horumarinaya xagga shaqeynta sare iyo lakabyo badan oo badan, taas oo u baahan iska caabbinta kulaylka sare ee walxaha substrate PCB sida dammaanad muhiim ah.Soo ifbaxa iyo horumarinta tignoolajiyada kor u qaadista cufnaanta sare ee ay matalaan SMT iyo CMT ayaa PCB ka dhigay mid aad iyo aad u badan oo aan kala go 'lahayn taageerada kulaylka sare ee substrate marka loo eego dalool yar, xariiq ganaax ah, iyo khafiifin.

Sidaa darteed, farqiga u dhexeeya FR-4 guud iyo sare Tg FR-4 waa in xoogga farsamada, xasiloonida cabbirka, adhesion, nuugista biyaha, iyo kulaylka kala-goynta walxaha ay ku jiraan xaalad kulul, gaar ahaan marka la kululeeyo ka dib nuugista qoyaanka.Waxaa jira kala duwanaansho xaalado kala duwan sida balaadhinta kulaylka, iyo alaabada Tg sare ayaa iska cad inay ka fiican yihiin qalabka caadiga ah ee PCB.

Sanadihii ugu dambeeyay, tirada macaamiisha u baahan taarikada daabacaadda Tg sare ayaa kordhay sanadba sanadka ka dambeeya.

Aqoonta maadiga guddiga PCB iyo heerarka (2007/05/06 17:15)

Waqtigan xaadirka ah, waxaa jira dhowr nooc oo looxyada naxaasta ah oo si weyn looga isticmaalo waddankayga, sifooyinkoodana waxay ku cad yihiin shaxda hoose: Noocyada looxyada naxaasta ah, aqoonta looxyada naxaasta ah.

Waxaa jira habab badan oo lagu kala sooci karo laminateyada naxaasta ah.Guud ahaan, marka loo eego qalabka xoojinta kala duwan ee guddiga, waxaa loo qaybin karaa: saldhigga warqadda, saldhigga maro ee guddiga pcb fiber fiber,

Saldhig isku-dhafan (taxane CEM), saldhig boodh-lakab badan oo dahaaran iyo saldhig shay gaar ah ( dhoobo, saldhig bir ah, iwm) shan qaybood.Haddii loo isticmaalo guddiga _)(^$RFSW#$%T

Xabagta xabagta ee kala duwan ayaa la kala saaray, CCI-ga warqad ku salaysan oo caadi ah.Haa: xabagta phenolic (XPC, XxxPC, FR-1, FR

-2, iwm), xabagta epoxy (FE-3), xabagta polyesterka iyo noocyo kale.Saldhigga maro fiber galaas ah ee caadiga ah CCL wuxuu leeyahay resin epoxy (FR-4, FR-5), kaas oo hadda ah nooca ugu badan ee loo isticmaalo saldhigga maro fiber galaas ah.Intaa waxaa dheer, waxaa jira resins kale oo gaar ah (maro fiber galaas ah, fiber polyamide, dhar aan tolmo lahayn, iwm sida qalab dheeraad ah): bismaleimide resin triazine modified (BT), polyimide resin (PI) , Diphenylene ether resin (PPO), lab. anhydride imine-styrene resin (MS), polycyanate resin, polyolefin resin, iwm. Marka loo eego waxqabadka ololka ee CCL, waxa loo qaybin karaa laba nooc oo loox ah: olol retardant (UL94-VO, UL94-V1) iyo non- Dab-demiska (UL94-HB).Hal ama labadii sano ee la soo dhaafay, iyada oo xoogga la saaray ilaalinta deegaanka, nooc cusub oo CCL ah oo aan ku jirin bromine ayaa laga soocay CCL-da ololka, kaas oo loo yaqaan "cagaaran ololka-dejinta CCL".Iyadoo horumarinta degdega ah ee tignoolajiyada alaabta elektiroonigga ah, waxaa jira shuruudaha waxqabadka sare ee cCL.Sidaa darteed, laga soo bilaabo kala-soocidda waxqabadka ee CCL, waxa loo qaybiyaa waxqabadka guud ee CCL, dielectric hoose CCL joogto ah, iska caabin kulayl sare CCL (guud ahaan L ee guddiga ayaa ka sarreeya 150 ° C), iyo hooseeyo ballaarinta kulaylka coefficient CCL (guud ahaan loo isticmaalo on substrates baakadaha)) iyo noocyo kale.Horumarinta iyo horumarka joogtada ah ee tignoolajiyada elektiroonigga ah, shuruudo cusub ayaa si joogto ah loogu soo bandhigaa agabka substrate-ka guddiga daabacan, taas oo kor u qaadeysa horumarka joogtada ah ee heerarka laminate ee naxaasta.Hadda, heerarka ugu muhiimsan ee alaabta substrate waa sida soo socota.

Heerarka qaranka Waqtigan xaadirka ah, halbeegyada qaranka ee dalkayga ee kala soocida agabka substrate pcb waxaa ka mid ah GB/T4721-47221992 iyo GB4723-4725-1992.Halbeegga loogu talagalay laminates-ka naxaasta ah ee Taiwan, Shiinaha waa heerka CNS, kaas oo ku saleysan halbeegga JI ee Japan., oo la sii daayay 1983. gfgfgfgggeeeejhjj

Heerarka ugu muhiimsan ee heerarka kale ee qaranka waa: JIS heerka Japan, ASTM, NEMA, MIL, IPC, ANSI, UL heerka Maraykanka, heerka Bs ee Boqortooyada Ingiriiska, DIN iyo heerka VDE ee Jarmalka, heerka NFC iyo UTE ee Faransiiska, CSA ee Heerarka Kanada, Halbeegga Australia AS, Halbeeggii FOCT ee Midowgii Soofiyeeti ee hore, heerka caalamiga ah ee IEC, iwm.

Alaab-qeybiyeyaasha agabka naqshadeynta PCB-ga asalka ah waxaa caadi ahaan isticmaala qof walba: ShengyiJiantao International, iwm.

● Dukumeenti la aqbalay: protel autocad powerpcb orcad gerber ama sabuurada koobi ee adag, iwm.

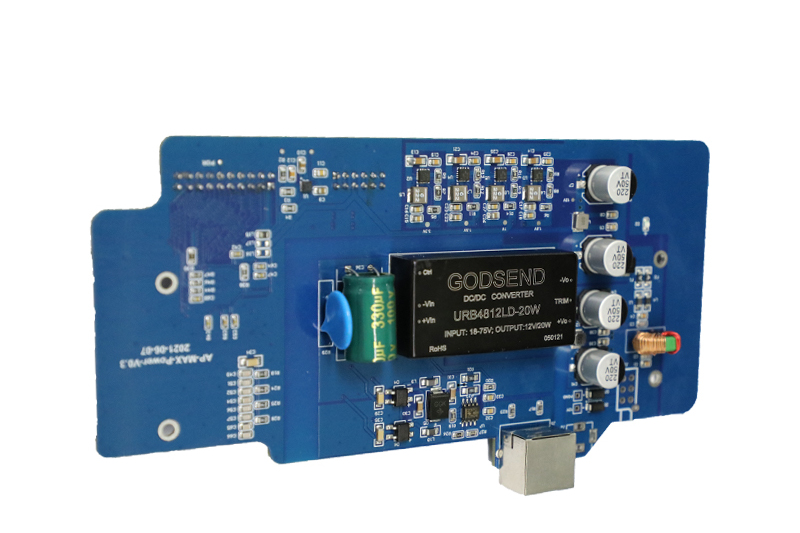

● Nooca saxanka: CEM-1, CEM-3 FR4, qalabka TG sare;

● Cabbirka looxa ugu badan: 600mm*700mm(24000mil*27500mil)

● Dhumucda looxa shaqada: 0.4mm-4.0mm(15.75mil-157.5mil)

● Lakabyada farsamaynta ugu badan: 16Lakab

● Dhumucdiisuna waxay tahay lakabka naxaasta: 0.5-4.0(oz)

● U dulqaadashada dhumucda saxanka oo dhammaatay: +/- 0.1mm(4mil)

● U adkeysiga cabbirka wax-qabashada: wax-shiidka kumbuyuutarka: 0.15mm (6mil) Shaambada dhimista: 0.10mm (4mil)

● Ballaca xariiqda ugu yar: 0.1mm (4mil) Awoodda xakamaynta ballaca laynka: <+-20%

● Dhexroorka qodista ugu yar ee alaabta la dhammeeyey: 0.25mm (10mil)

Dhammaatay dhexroorka daloolka feerka ugu yar: 0.9mm (35mil)

Dulqaadkii la dhameeyay: PTH: + -0.075mm (3mil)

NPTH: + -0.05mm (2mil)

● Dhumucdiisuna waxay dhammaatay: 18-25um (0.71-0.99mil)

● Meesha ugu yar ee SMT: 0.15mm (6mil)

● Dahaarka dusha sare: dahabka immersion kiimikaad, HASL, dahabka nikkel-ku dahaaran ee looxa oo dhan (dahab biyo/dahab jilicsan), shaashad xariir buluug ah, iwm.

● Dhumucda maaskarada alxanka ee looxa: 10-30μm (0.4-1.2mil)

● Xoogga diirka: 1.5N/mm (59N/mil)

● adkaanta maaskarada alxanka: >5H

● Awoodda xidhidhiyaha iska caabbinta alxanka: 0.3-0.8mm (12mil-30mil)

● Dielectric joogto ah: ε= 2.1-10.0

● caabbinta dahaarka: 10KΩ-20MΩ

● Caqabadda sifada: 60 ohm± 10%

● Naxdinta kulaylka: 288 ℃, 10 sekan

● Wargeeska guddiga la dhammeeyey: <0.7%

● Codsiga alaabta: qalabka isgaarsiinta, elektiroonigga baabuurta, qalabaynta, nidaamka meelaynta caalamiga ah, computer, MP4, korontada, qalabka guriga, iwm.

Waqtiga boostada: Mar-30-2023