Ukuhlukaniswa kusuka phansi kuya phezulu kungokulandelayo:

94HB/94VO/22F/CEM-1/CEM-3/FR-4

Imininingwane imi kanje:

I-94HB: Ikhadibhodi elivamile, elingashisi umlilo (impahla yebanga eliphansi kakhulu, i-die punching, ayikwazi ukusetshenziswa njengebhodi lamandla)

I-94V0: ikhadibhodi elibuyisela amalangabi (i-die punching)

I-22F: Ibhodi ye-fiber yengilazi enohlangothi olulodwa (i-die punching)

I-CEM-1: Ibhodi le-fiberglass elinohlangothi olulodwa (kumele libhodwe ngekhompyutha, lingashaywa)

I-CEM-3: Ibhodi le-semi-fiberglass elinamacala amabili (ngaphandle kwekhadibhodi elinamacala amabili, eliwumsebenzi ophansi kakhulu wamaphaneli anezinhlangothi ezimbili. Amaphaneli alula anezinhlangothi ezimbili angasebenzisa le nto, engu-5~10 yuan/isikwele. imitha ishibhile kune-FR-4)

I-FR-4: Ibhodi ye-fiberglass enezinhlangothi ezimbili

Impendulo engcono kakhulu

1.c Ukuhlukaniswa kwezakhiwo ezivimbela amalangabi kungahlukaniswa ngezinhlobo ezine: 94V—0/V-1/V-2 kanye no-94-HB

2. Prepreg: 1080=0.0712mm, 2116=0.1143mm, 7628=0.1778mm

3. I-FR4 CEM-3 iyibhodi, i-fr4 iyibhodi le-fiber yengilazi, i-cem3 iyinhlanganisela engaphansi

4. I-halogen-free ibhekisela ezintweni eziyisisekelo ezingenayo i-halogen (i-fluorine, i-bromine, i-iodine nezinye izakhi), ngoba i-bromine izokhiqiza igesi elinobuthi lapho lishiswa, elidingwa ukuvikelwa kwemvelo.

Ezinhlanu.I-Tg izinga lokushisa lokushintsha kwengilazi, okungukuthi, indawo yokuncibilika.

Ibhodi lesifunda kufanele likwazi ukumelana nelangabi, alikwazi ukushisa ezingeni elithile lokushisa, lingathambisa kuphela.Iphuzu lokushisa ngalesi sikhathi libizwa ngokuthi izinga lokushisa lokushintsha kwengilazi (iphuzu le-Tg), futhi leli nani lihlobene nokuzinza kwe-dimensional yebhodi le-PCB.

Liyini ibhodi lesekhethi ye-Tg PCB ephezulu kanye nezinzuzo zokusebenzisa i-Tg PCB ephezulu

Lapho izinga lokushisa eliphezulu lamabhodi aphrintiwe e-Tg likhuphukela endaweni ethile, i-substrate izoshintsha isuka "kwisimo sengilazi" ibe "isimo senjoloba", futhi izinga lokushisa ngalesi sikhathi libizwa ngokuthi izinga lokushisa lokuguqulwa kwengilazi (Tg) yebhodi.Okusho ukuthi, i-Tg izinga lokushisa eliphakeme kakhulu (° C.) lapho i-substrate ihlala iqinile.Okusho ukuthi, izinto ezijwayelekile ze-PCB substrate azigcini nje ngokuthambisa, ukukhubazeka, ukuncibilika, njll. emazingeni okushisa aphezulu, kodwa futhi zibonisa ukwehla okukhulu kwezakhiwo zemishini nekagesi (Ngicabanga ukuthi awufuni ukubona lesi simo emikhiqizweni yakho. ngokubheka ukuhlukaniswa kwamabhodi e-PCB. ).Sicela ungakopishi okuqukethwe kwalesi sizindalwazi

Ngokuvamile, i-Tg yepuleti ingaphezu kwama-degree angu-130, i-Tg ephakeme ngokuvamile inkulu kunama-degree angu-170, kanti i-Tg ephakathi ingaphezu kuka-150 degrees.

Ngokuvamile, amabhodi aphrintiwe e-PCB ane-Tg ≥ 170 ° C abizwa ngokuthi amabhodi aphrintiwe we-Tg aphezulu.

I-Tg ye-substrate iyanda, futhi ukumelana nokushisa, ukumelana nomswakama, ukumelana namakhemikhali, nokuzinza kwebhodi eliphrintiwe kuzothuthukiswa futhi kuthuthukiswe.Ukuphakama kwevelu ye-TG, kungcono ukumelana nezinga lokushisa kwebhodi, ikakhulukazi kwinqubo yokungenamthofu, kunezinhlelo zokusebenza ze-Tg eziphezulu.

I-Tg ephezulu isho ukumelana nokushisa okuphezulu.Ngokuthuthuka okusheshayo kwemboni ye-elekthronikhi, ikakhulukazi imikhiqizo ye-elekthronikhi emelwe amakhompyutha, ithuthukela ekusebenzeni okuphezulu kanye nezingqimba eziningi, okudinga ukumelana nokushisa okuphezulu kwe-PCB substrate materials njengesiqinisekiso esibalulekile.Ukuvela nokuthuthukiswa kobuchwepheshe bokukhweza obuphezulu obumelelwe i-SMT ne-CMT kwenze i-PCB yahluka kakhulu kusukela ekusekelweni kokumelana nokushisa okuphezulu kwe-substrate ngokuya ngembobo encane, umugqa ocolekile, kanye nokuncipha.

Ngakho-ke, umehluko phakathi kwe-FR-4 evamile kanye ne-Tg FR-4 ephezulu ukuthi amandla emishini, ukuzinza kwe-dimensional, ukunamathela, ukumuncwa kwamanzi, nokubola okushisayo kwempahla kusesimweni esishisayo, ikakhulukazi uma kushisa ngemva kokumuncwa komswakama.Kunomehluko ezimeni ezahlukahlukene njengokunwetshwa okushisayo, futhi imikhiqizo ephezulu ye-Tg ngokusobala ingcono kunezinto ezijwayelekile ze-PCB substrate.

Eminyakeni yakamuva, inani lamakhasimende adinga amabhodi aphrintiwe we-Tg aphezulu liye landa unyaka nonyaka.

Ulwazi olubalulekile lwebhodi le-PCB namazinga (2007/05/06 17:15)

Njengamanje, kunezinhlobo eziningana zamabhodi ezembatho zethusi asetshenziswa kabanzi ezweni lami, futhi izici zawo zikhonjiswe etafuleni elingezansi: izinhlobo zamabhodi ezembatho zethusi, ulwazi lwamabhodi e-copper-clad

Kunezindlela eziningi zokuhlukanisa ama-laminates e-copper clad.Ngokuvamile, ngokwezinto ezihlukahlukene zokuqinisa ibhodi, zingahlukaniswa zibe: isisekelo sephepha, isisekelo sendwangu ye-glass fiber pcb board,

Isisekelo esiyinhlanganisela (uchungechunge lwe-CEM), isisekelo sebhodi lezendlalelo eziningi elaminethiwe kanye nesisekelo sezinto ezikhethekile (i-ceramic, isisekelo esiyisisekelo sensimbi, njll.) izigaba ezinhlanu.Uma isetshenziswa ibhodi _)(^$RFSW#$%T

Izinamatheliso ze-resin ezihlukene zihlukaniswa, i-CCI esekelwe ephepheni evamile.Yebo: i-phenolic resin (XPC, XxxPC, FR-1, FR

-2, njll.), i-epoxy resin (FE-3), i-polyester resin nezinye izinhlobo.Isisekelo sendwangu yengilazi yengilazi evamile ye-CCL ine-epoxy resin (FR-4, FR-5), okwamanje okuwuhlobo olusetshenziswa kakhulu lwesisekelo sendwangu yengilazi.Ngaphezu kwalokho, kunezinye izinhlaka ezikhethekile (indwangu ye-fiber yengilazi, i-polyamide fiber, indwangu engalukiwe, njll. njengezinto ezengeziwe): i-bismaleimide modified triazine resin (BT), i-polyimide resin (PI) , i-Diphenylene ether resin (PPO), i-maleic i-anhydride imine-styrene resin (MS), i-polycyanate resin, i-polyolefin resin, njll. Ngokokusebenza kwe-CCL kwe-flame retardant, ingahlukaniswa ngezinhlobo ezimbili zamabhodi: i-flame retardant (UL94-VO, UL94-V1) kanye ne-non- i-flame retardant (UL94-HB).Ngonyaka owodwa noma emibili edlule, ngokugcizelela okwengeziwe ekuvikelweni kwemvelo, uhlobo olusha lwe-CCL olungenayo i-bromine luye lwahlukaniswa ne-CCL ye-flame-retardant, engabizwa ngokuthi "i-CCL eluhlaza okotshani".Ngokuthuthuka okusheshayo kobuchwepheshe bomkhiqizo we-elekthronikhi, kunezidingo zokusebenza eziphezulu ze-cCL.Ngakho-ke, kusukela ekuhlukaniseni ukusebenza kwe-CCL, ihlukaniswe yaba ukusebenza okujwayelekile kwe-CCL, i-CCL ephansi ye-dielectric engaguquki, i-CCL yokumelana nokushisa okuphezulu (ngokuvamile i-L yebhodi ingaphezu kuka-150 ° C), kanye ne-CCL yokwandisa okushisayo okuphansi (ngokuvamile isetshenziswa ama-packaging substrates) ) nezinye izinhlobo.Ngokuthuthuka kanye nenqubekelaphambili eqhubekayo yobuchwepheshe be-elekthronikhi, izidingo ezintsha zihlala zibekwe phambili ezintweni eziphrintiwe zebhodi le-substrate, ngaleyo ndlela kuthuthukiswe ukuthuthukiswa okuqhubekayo kwamazinga e-copper clad laminate.Njengamanje, izindinganiso eziyinhloko zezinto ze-substrate zimi kanje.

①Amazinga kazwelonke Njengamanje, izindinganiso kazwelonke zezwe lami zokuhlukaniswa kwe-substrate material pcb board zihlanganisa i-GB/T4721-47221992 kanye ne-GB4723-4725-1992.Izinga le-copper clad laminates e-Taiwan, i-China iyindinganiso ye-CNS, esekelwe ku-Japanese JIs standard., eyakhishwa ngo-1983. gfgfgfggdgeeeejhjj

② Izindinganiso eziyinhloko zamanye amazinga kazwelonke yilezi: Izinga le-JIS lase-Japan, i-ASTM, i-NEMA, i-MIL, i-IPc, i-ANSI, izinga le-UL lase-United States, izinga le-Bs lase-United Kingdom, izinga le-DIN ne-VDE laseJalimane, i-NFC ne-UTE ejwayelekile yase-France, i-CSA ye-Canada Standards, i-AS yase-Australia ejwayelekile, izinga le-FOCT langaphambili le-Soviet Union, izinga lamazwe ngamazwe le-IEC, njll.

Abahlinzeki bezinto zokuqala zokwakha ze-PCB bavame ukusetshenziswa yiwo wonke umuntu: i-Shengyi\Jiantao\International, njll.

● Amadokhumenti amukelwayo: i-protel autocad powerpcb orcad gerber noma ibhodi lekhophi eliqinile, njll.

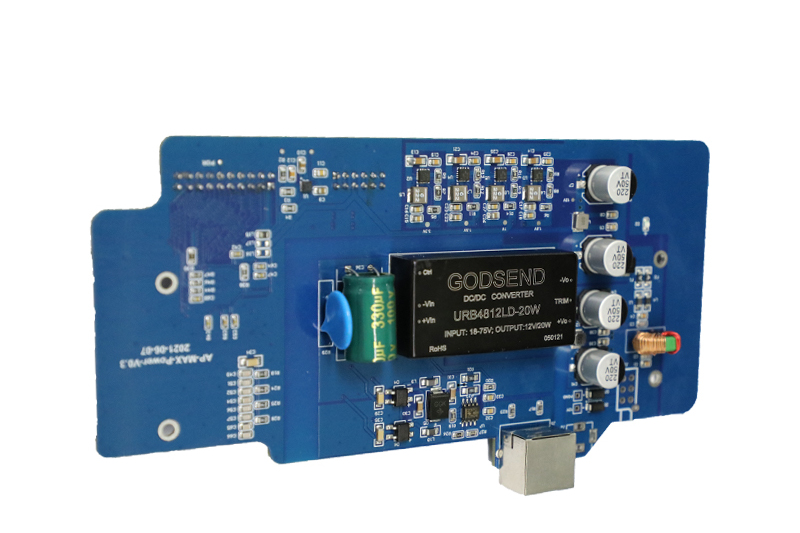

● Uhlobo lwepuleti: CEM-1, CEM-3 FR4, impahla ye-TG ephezulu;

● Ubukhulu bosayizi webhodi: 600mm*700mm(24000mil*27500mil)

● Ugqinsi lwebhodi lokucubungula: 0.4mm-4.0mm(15.75mil-157.5mil)

● Izendlalelo eziphezulu zokucubungula: 16Layers

● Ugqinsi lwesendlalelo se-copper: 0.5-4.0(oz)

● Iqedile ukubekezelela ubukhulu bepuleti: +/-0.1mm(4mil)

● Ukumelana nobukhulu bokubumba: Ukugaya ikhompuyutha: 0.15mm (6mil) Ukunyathela i-Die: 0.10mm (4mil)

● Ububanzi/isikhala somugqa omncane: 0.1mm (4mil) Ikhono lokulawula ububanzi bomugqa: <+-20%

● Ubukhulu obuncane bokubhoboza ububanzi bomkhiqizo oqediwe: 0.25mm (10mil)

Kuqedwe ubuncane bembobo yokubhoboza ububanzi: 0.9mm (35mil)

Kuqediwe ukubekezelela imbobo: PTH: +-0.075mm (3mil)

I-NPTH: +-0.05mm (2mil)

● Ugqinsi lwethusi lwembobo eqediwe: 18-25um (0.71-0.99mil)

● Iphimbo elincane le-SMT: 0.15mm (6mil)

● I-surface coating: igolide lokucwiliswa ngamakhemikhali, i-HASL, igolide eligcwele ibhodi eligcwele i-nickel (amanzi/igolide elithambile), iglue eluhlaza okwesibhakabhaka sesikrini sikasilika, njll.

● Ukujiya kwemaski yesoda ebhodini: 10-30μm (0.4-1.2mil)

● Amandla ekhasi: 1.5N/mm (59N/mil)

● Ukuqina kwemaski ye-solder: >5H

● Umthamo wokuxhuma we-solder: 0.3-0.8mm (12mil-30mil)

● I-Dielectric constant: ε= 2.1-10.0

● Ukumelana ne-insulation: 10KΩ-20MΩ

● I-impedance yesici: 60 ohm±10%

● Ukushaqeka okushisayo: 288℃, 10 sec

● I-Warpage yebhodi eliqediwe: < 0.7%

● Isicelo somkhiqizo: okokusebenza kokuxhumana, izinto zikagesi zezimoto, i-instrumentation, isistimu yokuma komhlaba jikelele, ikhompuyutha, i-MP4, ukunikezwa kwamandla kagesi, izinto zikagesi zasekhaya, njll.

Isikhathi sokuthumela: Mar-30-2023