PCBana yin ta ne ta hanyar fasahar bugu ta lantarki, don haka ana kiranta da bugu na bugu.Kusan kowane nau'in kayan lantarki, tun daga kunne, baturi, lissafin lissafi, zuwa kwamfuta, na'urorin sadarwa, jiragen sama, tauraron dan adam, muddin ana amfani da kayan lantarki kamar na'urori masu haɗaka, ana amfani da PCBs don haɗin wutar lantarki a tsakanin su.

PCB da PCBA su ne PCBs masu abubuwan da ba a saka su ba, PCBA (Printed Circuit Board Assembly), wato PCB sanye take da kayan lantarki (kamar chips, connectors, resistors, capacitors, inductor, etc.).

PCB asalin

A shekara ta 1925, Charles Ducas a Amurka (wanda ya kirkiro hanyar ƙari) ya buga tsarin da'ira akan wani abin rufe fuska, sannan ya yi nasarar yin madugu a matsayin na'ura ta hanyar lantarki.

A cikin 1936, Baturen Australiya Paul Eisler (wanda ya kafa hanyar ragewa) shine farkon wanda ya fara amfani da allunan da'ira a cikin rediyo.

A cikin 1943, Amurkawa sun yi amfani da fasahar a rediyon soja.A cikin 1948, Amurka a hukumance ta amince da ƙirƙira don amfanin kasuwanci.

An yi amfani da allunan da'ira da aka buga kawai tun tsakiyar shekarun 1950, kuma a yau sun mamaye masana'antar lantarki.

Kwamfutocin da'irar da aka buga sun haɓaka daga Layer-Layer zuwa mai gefe biyu, Multi-Layer da sassauƙa, kuma har yanzu suna kula da abubuwan haɓaka nasu.Saboda ci gaba da ci gaba a cikin jagorancin madaidaicin madaidaici, haɓaka mai yawa da aminci, ci gaba da raguwa a cikin girman, raguwar farashi da haɓaka aikin aiki, kwamitocin da'irar da aka buga har yanzu suna kula da karfi mai karfi a cikin ci gaban kayan aikin lantarki na gaba.

Tattaunawa game da ci gaban ci gaba na gaba na fasahar masana'anta da aka buga a gida da waje suna da daidaituwa, wato, zuwa girma mai yawa, daidaitattun daidaito, fa'ida mai kyau, waya na bakin ciki, ƙaramin farar, babban aminci, Multi-Layer, watsawa mai sauri. , Hasken nauyi Game da samarwa, yana haɓakawa a cikin hanyar haɓaka yawan aiki, rage farashi, rage ƙazanta, da daidaitawa ga nau'o'in nau'i-nau'i da ƙananan kayan aiki.

Matsayin PCB

Kafin allon da'irar da aka buga, an haɗa haɗin haɗin kai tsaye ta hanyar wayoyi don samar da cikakkiyar da'ira.

Bayan kayan aikin lantarki sun karɓi allunan da'ira da aka buga, saboda daidaiton nau'ikan allunan da'irar da aka buga, ana guje wa kurakurai a cikin wayoyin hannu.

Kwamitin da'irar da aka buga zai iya ba da tallafi na injiniya don gyarawa da haɗa nau'o'in kayan lantarki daban-daban kamar haɗaɗɗun da'irori, kammala wayoyi da haɗin lantarki ko rufin lantarki tsakanin nau'ikan lantarki daban-daban kamar haɗaɗɗun da'irori, da kuma samar da halayen lantarki da ake buƙata, kamar halayen Impedance, da sauransu, na iya samar da zane-zanen abin rufe fuska na solder don siyarwar atomatik, da samar da haruffan ganowa da zane-zane don shigar da bangaren, dubawa, da kiyayewa.

Rarraba PCB

1. Rarraba da manufa

Allolin da'ira na farar hula (masu amfani): bugu na allo da ake amfani da su a cikin kayan wasan yara, kyamarori, talabijin, kayan sauti, wayoyin hannu, da sauransu.

Allolin da'ira bugu na masana'antu (kayan aiki): allunan da'ira bugu da ake amfani da su wajen tsaro, motoci, kwamfutoci, injinan sadarwa, kayan kida, da sauransu.

Allolin da'irar bugu na soja: allunan da'ira bugu da ake amfani da su a sararin samaniya da radar, da sauransu.

2. Rarraba ta nau'in substrate

Takarda-tushen buga kewaye allon: phenolic takarda-tushen buga kewaye allon, epoxy takarda-tushen buga kewaye allon, da dai sauransu.

Gilashin zane na tushen bugu allon allon: epoxy gilashin zane-tushen bugu da aka buga, PTFE gilashin zane na tushen bugu allon allon, da dai sauransu.

Roba fiber bugu kewaye allon: epoxy roba fiber buga kewaye hukumar, da dai sauransu.

Organic film substrate buga kewaye hukumar: nailan film buga kewaye hukumar, da dai sauransu.

Ceramic substrate buga allon kewaye.

Ƙarfe na tushen bugu da allunan kewayawa.

3. Rarraba ta tsari

Dangane da tsarin, ana iya raba allunan da'irar da aka buga zuwa ƙayyadaddun allunan da'ira, madaukai masu sassauƙa da kuma allunan da'ira masu sassauƙa.

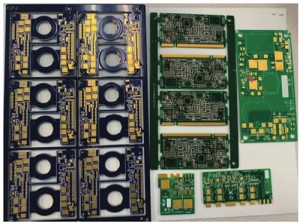

4. Rarrabe bisa ga adadin yadudduka

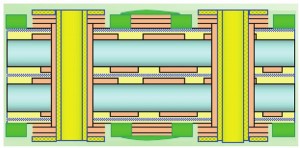

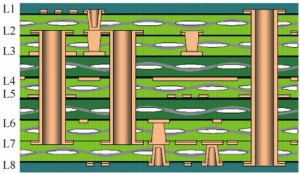

Dangane da adadin yadudduka, ana iya raba allunan da'irar da aka buga zuwa allunan gefe guda, allon fuska biyu, allunan Layer Layer da allon HDI ( allunan haɗin haɗin kai mai girma ).

1) Gefe guda

Allo mai gefe guda yana nufin allon kewayawa wanda aka yi wa waya a gefe ɗaya kawai (bangaren siyarwa) na allon kewayawa, kuma duk abubuwan da aka haɗa, alamar abubuwan da aka rubuta da alamar rubutu ana sanya su a gefe guda (bangaren ɓangaren).

Babban fasali na panel mai gefe guda ɗaya shine ƙananan farashinsa da tsarin sarrafawa mai sauƙi.Duk da haka, tun da za a iya aiwatar da wayoyi a kan wani wuri ɗaya kawai, igiyoyin waya sun fi wuya, kuma na'urar tana da wuyar gazawa, don haka ya dace da wasu ƙananan hanyoyi masu sauƙi.

2) Gefe biyu

An yi amfani da katako mai gefe guda biyu a bangarorin biyu na allon rufewa, gefe ɗaya ana amfani da shi azaman saman saman, ɗayan kuma ana amfani da shi azaman ƙasa.Yaduddukan saman da na ƙasa ana haɗa su ta hanyar lantarki ta hanyar hanyar sadarwa.

Yawancin lokaci, an sanya abubuwan da aka gyara a kan katako mai layi biyu a saman Layer;duk da haka, wasu lokuta ana iya sanya abubuwan haɗin gwiwa a kan sassan biyu don rage girman allo.Jirgin mai Layer biyu yana nuna matsakaicin farashi da sauƙin wayoyi.Shi ne nau'in da aka fi amfani dashi a cikin allunan kewayawa na yau da kullun.

3) Multi-Layer allon

Allolin da'ira da aka buga tare da fiye da yadudduka biyu ana kiransu tare da allunan multilayer.

4) HDI

Kwamitin HDI allon kewayawa ne mai girman girman rarraba da'ira ta amfani da fasahar rami da aka binne makafi.

Tsarin PCB

PCB ne yafi hada da jan karfe clad laminates (Copper Clad Laminates, CCL), prepreg (PP takardar), tagulla tsare (Copper Foil), solder mask (kuma aka sani da solder mask) (Solder Mask).A lokaci guda, don kare fallen jan karfe da aka fallasa a saman da kuma tabbatar da tasirin walda, Hakanan wajibi ne don aiwatar da jiyya a kan PCB, wani lokacin kuma ana yin alama da haruffa.

1) Copper Clad Laminate

Copper-clad laminate (CCL), wanda ake magana da shi azaman laminate mai ɗorewa ko tagulla, shine ainihin abu don kera kwalayen da'ira.Ya ƙunshi wani dielectric Layer (gudu, gilashin fiber) da kuma high-tsarki madugu (tagulla foil).wanda ya ƙunshi kayan haɗin gwiwa.

Sai a shekarar 1960 ne kwararrun masana'antun suka yi amfani da foil na formaldehyde guduro tagulla a matsayin tushen abu don yin PCBs masu gefe guda, kuma suka sanya su cikin kasuwa na masu rikodin rikodin, na'urar rikodin bidiyo, masu rikodin bidiyo, da sauransu. -gefe ta-rami jan karfe plating fasahar masana'antu, zafi juriya, size Stable epoxy gilashin substrates an yi amfani da ko'ina ya zuwa yanzu.A zamanin yau, FR4, FR1, CEM3, yumbura da faranti na Teflon ana amfani da su sosai.

A halin yanzu, mafi yawan amfani da PCB da aka yi ta hanyar etching shine a zaɓen etch akan allon tagulla don samun tsarin da'irar da ake buƙata.Lamintin tagulla yana ba da ayyuka guda uku na gudanarwa, rufi da goyan baya akan dukkan allon da'ira da aka buga.Ayyukan aiki, inganci da farashin masana'anta na allon da'irar da aka buga sun dogara da yawa akan laminates ɗin jan ƙarfe

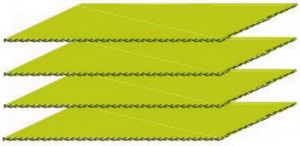

2) Prepreg

Prepreg, wanda kuma aka sani da takardar PP, yana ɗaya daga cikin manyan kayan aikin samar da allunan multilayer.An fi haɗa shi da guduro da kayan ƙarfafawa.An rarraba kayan ƙarfafawa zuwa gilashin fiber gilashi (wanda ake kira gilashin gilashi), tushe na takarda da kayan haɗin kai.

Yawancin prepregs (zanen liƙa) da ake amfani da su wajen samar da allunan da'ira da aka buga da yawa suna amfani da zanen gilashi azaman kayan ƙarfafawa.Kayan da aka yi da bakin ciki wanda aka yi ta hanyar zubar da zanen gilashin da aka bi da shi tare da manne mai guduro, sannan an riga an gasa shi ta hanyar magani mai zafi ana kiransa prepreg.Prepregs suna yin laushi ƙarƙashin zafi da matsa lamba kuma suna ƙarfafa lokacin da aka sanyaya.

Tun da yawan nau'in yadin da aka yi a kowace raka'a tsawon gilashin gilashi a cikin warp da kwatance ya bambanta, ya kamata a ba da hankali ga warp da gyare-gyare na prepreg lokacin yankan.Gabaɗaya, jagorar warp (yankin da keɓaɓɓen zanen gilashin) an zaɓi shi azaman gajeriyar hanyar gefen allon samarwa, kuma jagorar saƙar ita ce Alƙawar gefen tsayin allon samarwa shine don tabbatar da shimfidar wuri allon allo da kuma hana tsarin samarwa daga karkatar da gurɓatacce bayan an gama zafi.

3) Rufin tagulla

Bakin jan karfe siriri ne, mai ci gaba da zama foil na karfe da aka ajiye akan gindin allon da'irar.A matsayin jagorar PCB, ana iya haɗa shi cikin sauƙi zuwa rufin insulating kuma an tsara shi don samar da tsarin kewayawa.

Na kowa masana'antu tagulla foil za a iya raba biyu Categories: birgima jan karfe (RA copper foil) da electrolytic jan karfe (ED jan karfe tsare):

Gilashin jan ƙarfe na jan ƙarfe yana da kyawawan ductility da sauran halaye, kuma shine foil ɗin jan ƙarfe da aka yi amfani da shi a farkon tsarin jirgi mai laushi;

Bakin jan ƙarfe na lantarki yana da fa'idar ƙananan farashin masana'anta fiye da birgima na tagulla

4) Solder mask

Layin juriya na solder yana nufin ɓangaren allon da'ira da aka buga tare da tawada juriya.

Solder resist tawada yawanci kore ne, wasu kuma suna amfani da ja, baki da shuɗi, da sauransu, don haka solder resist tawada galibi ana kiransa koren mai a masana'antar PCB.Yana da madaidaicin kariyar allo na allon da'ira da aka buga, wanda zai iya hana danshi, Anti-lalacewa, anti-mildew da abrasion na inji, da sauransu, amma kuma yana hana sassa daga waldawa zuwa wuraren da ba daidai ba.

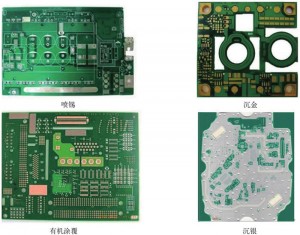

5) Maganin saman

“Surface” kamar yadda aka yi amfani da shi anan yana nufin wuraren haɗin kan PCB waɗanda ke ba da haɗin wutar lantarki tsakanin kayan lantarki ko wasu sifofi da da’irori akan PCB, kamar wuraren haɗin pads ko haɗin haɗin gwiwa.Solderability na danda tagulla da kanta yana da kyau sosai, amma yana da sauƙi oxidized da gurɓata lokacin da aka fallasa shi zuwa iska, don haka ya kamata a rufe fim ɗin kariya a saman jan ƙarfe maras kyau.

Common PCB surface jiyya matakai hada gubar HASL, gubar-free HASL, Organic shafi (Organic Solderability Preservatives, OSP), immersion zinariya, immersion azurfa, immersion tin da zinariya-plated yatsunsu, da dai sauransu Tare da ci gaba da inganta muhalli kare dokokin, akwai. An dakatar da tsarin HASL jagora a hankali.

6) Halaye

Halin shine rubutun rubutu, akan saman saman PCB, yana iya zama ba ya nan, kuma ana amfani dashi gabaɗaya don sharhi.

Yawancin lokaci, don sauƙaƙe shigarwa da kiyaye da'ira, ana buga alamun tambarin da ake buƙata da lambobin rubutu a saman saman da ƙananan saman allon da aka buga, kamar alamomin sassan da ƙimar ƙima, sifofi na sassa da tamburan masana'anta, samarwa. kwanakin jira.

Yawanci ana buga haruffa ta hanyar bugu na allo

Lokacin aikawa: Maris 11-2023