PCBamapangidwa ndi teknoloji yosindikizira pakompyuta, choncho amatchedwa bolodi losindikizidwa.Pafupifupi mitundu yonse ya zida zamagetsi, kuyambira m'makutu, mabatire, zowerengera, makompyuta, zida zoyankhulirana, ndege, ma satelayiti, malinga ngati zida zamagetsi monga mabwalo ophatikizika zimagwiritsidwa ntchito, ma PCB amagwiritsidwa ntchito polumikizira magetsi pakati pawo.

PCB ndi PCBA ndi PCBs ndi zigawo unmounted, PCBA (Printed Circuit Board Assembly), ndiko kuti, PCBs okonzeka ndi zigawo zamagetsi (monga tchipisi, zolumikizira, resistors, capacitors, inductors, etc.).

Chiyambi cha PCB

Mu 1925, Charles Ducas ku United States (woyambitsa njira yowonjezera) adasindikiza kachitidwe ka dera pa gawo lapansi loteteza, ndiyeno adapanga kondakitala ngati waya ndi electroplating.

Mu 1936, Paul Eisler wa ku Austria (woyambitsa njira yochotsera) anali woyamba kugwiritsa ntchito matabwa osindikizira pawailesi.

Mu 1943, anthu aku America adagwiritsa ntchito lusoli pawailesi yankhondo.Mu 1948, dziko la United States linavomereza mwalamulo kupangidwa kwa malonda.

Ma board ozungulira osindikizidwa akhala akugwiritsidwa ntchito kwambiri kuyambira pakati pa zaka za m'ma 1950, ndipo lero akulamulira makampani opanga zamagetsi.

Ma board ozungulira osindikizidwa apangidwa kuchokera ku gulu limodzi kupita ku mbali ziwiri, zosanjikiza zambiri komanso zosinthika, ndipo amasungabe njira zawo zachitukuko.Chifukwa cha chitukuko chosalekeza cha njira yolondola kwambiri, kachulukidwe kakang'ono komanso kudalirika kwakukulu, kuchepetsa kukula, kuchepetsa mtengo ndi kupititsa patsogolo ntchito, matabwa osindikizira adakalibe amphamvu pakupanga zida zamagetsi zamtsogolo.

Zokambirana za tsogolo lachitukuko chaukadaulo wopangidwa ndi bolodi losindikizidwa kunyumba ndi kunja ndizokhazikika, ndiko kuti, kuchulukira kwakukulu, kulondola kwambiri, kabowo kakang'ono, waya woonda, phula laling'ono, kudalirika kwakukulu, kusanjikiza kosiyanasiyana, kufalitsa mwachangu. , Kulemera kopepuka Pankhani ya kupanga, ikukula m'njira yowonjezera zokolola, kuchepetsa ndalama, kuchepetsa kuipitsidwa, ndi kusinthasintha kupanga mitundu yambiri ndi yaing'ono.

Ntchito ya PCB

Bungwe la dera losindikizidwa lisanawonekere, kugwirizanitsa pakati pa zipangizo zamagetsi kunalumikizidwa mwachindunji ndi mawaya kuti apange dera lonse.

Pambuyo pazida zamagetsi zitenga matabwa osindikizira, chifukwa cha kugwirizana kwa matabwa osindikizira ofanana, zolakwika mu wiring pamanja zimapewedwa.

Bolodi losindikizidwa lamagetsi limatha kupereka chithandizo chamakina kukonza ndi kusonkhanitsa zida zosiyanasiyana zamagetsi monga mabwalo ophatikizika, kumaliza ma waya ndi kulumikizana kwamagetsi kapena kutchinjiriza kwamagetsi pakati pazigawo zosiyanasiyana zamagetsi monga mabwalo ophatikizika, ndikupereka mawonekedwe amagetsi ofunikira, monga mawonekedwe a Impedance, etc., atha kupereka solder chigoba graphics kuti soldering basi, ndi kupereka zizindikiro chizindikiritso ndi zithunzi kuyikapo, kuyendera, ndi kukonza.

Gawo la PCB

1. Kugawa ndi cholinga

Ma board osindikizidwa a anthu wamba (ogula): matabwa osindikizira omwe amagwiritsidwa ntchito muzoseweretsa, makamera, ma TV, zida zomvera, mafoni am'manja, ndi zina.

Industrial kusindikizidwa matabwa dera (zida): kusindikizidwa matabwa dera ntchito chitetezo, magalimoto, makompyuta, makina kulankhulana, zida, etc.

Ma board ozungulira ankhondo: matabwa osindikizira omwe amagwiritsidwa ntchito muzamlengalenga ndi radar, etc.

2. Gulu ndi mtundu wa gawo lapansi

Mapepala opangidwa ndi mapepala osindikizidwa: mapepala a phenolic opangidwa ndi mapepala, mapepala osindikizira a epoxy, etc.

Ma board ozungulira agalasi opangidwa ndi nsalu: ma epoxy galasi opangidwa ndi matabwa osindikizidwa, magalasi a PTFE opangidwa ndi magalasi osindikizidwa, etc.

Synthetic CHIKWANGWANI kusindikizidwa dera bolodi: epoxy kupanga CHIKWANGWANI kusindikizidwa dera bolodi, etc.

Organic filimu gawo lapansi kusindikizidwa dera bolodi: nayiloni filimu kusindikizidwa dera bolodi, etc.

Ceramic gawo lapansi losindikizidwa matabwa ozungulira.

Zitsulo pachimake zochokera kusindikizidwa dera matabwa.

3. Kugawa ndi kamangidwe

Malinga ndi kapangidwe kake, matabwa osindikizidwa amatha kugawidwa kukhala matabwa olimba osindikizidwa, matabwa osinthika osindikizidwa komanso matabwa ozungulira okhazikika.

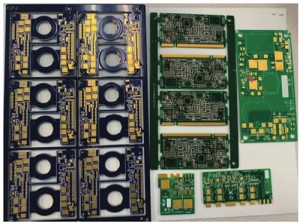

4. Amasankhidwa molingana ndi kuchuluka kwa zigawo

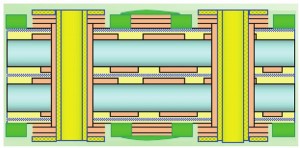

Malingana ndi chiwerengero cha zigawo, matabwa osindikizira amatha kugawidwa kukhala matabwa a mbali imodzi, matabwa a mbali ziwiri, matabwa amitundu yambiri ndi ma HDI board (ma board-high-density interconnect board).

1) Mbali imodzi

Bolodi lokhala ndi mbali imodzi limatanthawuza bolodi la dera lomwe limayikidwa mbali imodzi yokha (mbali ya soldering) ya bolodi la dera, ndipo zigawo zonse, zolemba zamagulu ndi zolemba zolemba zimayikidwa mbali inayo (gawo lachigawo).

Chinthu chachikulu cha gulu limodzi la mbali imodzi ndi mtengo wake wotsika komanso njira yosavuta yopangira.Komabe, popeza mawaya amatha kuchitidwa pamtunda umodzi, mawayawa ndi ovuta kwambiri, ndipo mawaya amatha kulephera, choncho ndi oyenera mabwalo ena osavuta.

2) Mbali ziwiri

Bolodi lokhala ndi mbali ziwiri limapangidwa ndi waya kumbali zonse za bolodi lotetezera, mbali imodzi imagwiritsidwa ntchito ngati pamwamba, ndipo mbali inayo imagwiritsidwa ntchito ngati pansi.Pamwamba ndi pansi zigawo ndi magetsi olumikizidwa kudzera vias.

Kawirikawiri, zigawo pa bolodi la zigawo ziwiri zimayikidwa pamwamba;komabe, nthawi zina zigawo zimatha kuikidwa pazigawo zonse ziwiri kuti muchepetse kukula kwa bolodi.Bolodi yamitundu iwiri imadziwika ndi mtengo wotsika komanso mawaya osavuta.Ndiwo mtundu womwe umagwiritsidwa ntchito kwambiri pama board wamba wamba.

3) Gulu lamitundu yambiri

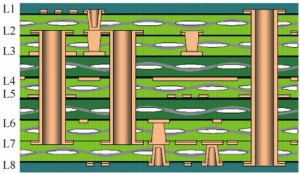

Ma board ozungulira osindikizidwa okhala ndi magawo opitilira awiri amatchulidwa pamodzi kuti ma multilayer board.

4) HDI board

Gulu la HDI ndi bolodi lozungulira lomwe lili ndi kachulukidwe kakang'ono kagawo kakang'ono kamene kamagwiritsa ntchito makina ang'onoang'ono akhungu okwiriridwa.

PCB kapangidwe

PCB makamaka amapangidwa ndi copper clad laminates (Copper Clad Laminates, CCL), prepreg (PP pepala), zojambula zamkuwa (Copper Foil), solder mask (omwe amadziwikanso kuti solder mask) (Solder Mask).Pa nthawi yomweyo, pofuna kuteteza poyera mkuwa zojambulazo pamwamba ndi kuonetsetsa kuwotcherera zotsatira, m'pofunikanso kuchita pamwamba mankhwala pa PCB, ndipo nthawi zinanso chizindikiro ndi zilembo.

1) Copper Clad Laminate

Copper-clad laminate (CCL), yotchedwa copper-clad laminate kapena copper-clad laminate, ndiye maziko opangira matabwa osindikizira.Amapangidwa ndi dielectric wosanjikiza (resin, galasi CHIKWANGWANI) ndi mkulu-kuyera conductor (zojambula zamkuwa).zopangidwa ndi zinthu zophatikizika.

Sizinafike mpaka 1960 pomwe opanga akatswiri adagwiritsa ntchito zojambula zamkuwa za formaldehyde resin monga maziko opangira ma PCB ambali imodzi, ndikuyika pamsika wa osewera, zojambulira, zojambulira mavidiyo, ndi zina zambiri. -kupyolera mu dzenje ukadaulo wopanga mkuwa, kukana kutentha, kukula Magawo agalasi okhazikika a epoxy akhala akugwiritsidwa ntchito kwambiri mpaka pano.Masiku ano, FR4, FR1, CEM3, mbale za ceramic ndi mbale za Teflon zimagwiritsidwa ntchito kwambiri.

Pakali pano, ambiri ntchito PCB opangidwa ndi etching njira ndi kusankha etch pa bolodi mkuwa atavala kupeza chofunika dera chitsanzo.Chovala chamkuwa cha laminate makamaka chimapereka ntchito zitatu za conduction, insulation ndi kuthandizira pa bolodi lonse losindikizidwa.Magwiridwe, khalidwe ndi kupanga mtengo wa matabwa ozungulira osindikizidwa zimadalira kwambiri pazitsulo zamkuwa zokhala ndi mkuwa

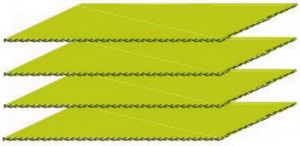

2) Prepreg

Prepreg, yomwe imadziwikanso kuti PP pepala, ndi imodzi mwazinthu zazikulu popanga matabwa ambiri.Amapangidwa makamaka ndi utomoni ndi zida zolimbikitsira.Zida zolimbikitsira zimagawidwa munsalu zamagalasi (zotchedwa nsalu zamagalasi), maziko a pepala ndi zida zophatikizika.

Ambiri mwa prepregs (mapepala zomatira) ntchito kupanga multilayer kusindikizidwa dera matabwa ntchito galasi nsalu monga kulimbikitsa chuma.Chitsamba chopyapyala chomwe chimapangidwa ndikuyika nsalu yagalasi yopangidwa ndi utomoni ndi guluu, kenako zophikidwa kale ndi kutentha zimatchedwa prepreg.Prepregs amafewetsa pansi pa kutentha ndi kukakamizidwa ndi kulimba pamene utakhazikika.

Popeza chiwerengero cha zingwe ulusi pa unit kutalika kwa galasi nsalu mu njira warp ndi weft ndi osiyana, chidwi ayenera kuperekedwa kwa warp ndi weft malangizo a prepreg podula.Nthawi zambiri, njira ya warp (njira yomwe nsalu yagalasi imapindika) imasankhidwa ngati mbali yaying'ono ya bolodi yopanga, ndipo mayendedwe a weft ndi Mayendedwe a mbali yayitali ya gulu lopanga ndikuwonetsetsa kuti flatness ya bolodi pamwamba ndi kuteteza gulu kupanga kupotozedwa ndi kupunduka pambuyo kutenthedwa.

3) Chojambula chamkuwa

Chojambula chamkuwa ndi chojambula chachitsulo chopyapyala, chosalekeza chomwe chimayikidwa pamunsi pa bolodi yozungulira.Monga kondakitala wa PCB, izo mosavuta womangidwa kwa wosanjikiza insulating ndi zinakhazikika kupanga dera chitsanzo.

Zojambula zamkuwa wamba zitha kugawidwa m'magulu awiri: zojambulazo zamkuwa (zojambula zamkuwa za RA) ndi zojambulazo zamkuwa za electrolytic (ED copper zojambulazo):

Chophimba chamkuwa chimakhala ndi ductility wabwino ndi makhalidwe ena, ndipo ndi zojambulazo zamkuwa zomwe zimagwiritsidwa ntchito poyambira ndondomeko yofewa;

Chojambula chamkuwa cha Electrolytic chili ndi mwayi wotsika mtengo wopangira kuposa zojambula zamkuwa zokulungidwa

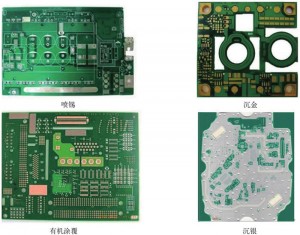

4) Chigoba cha solder

The solder kukana wosanjikiza amatanthauza mbali ya bolodi kusindikizidwa dera ndi solder kukana inki.

Solder kukana inki nthawi zambiri wobiriwira, ndipo ochepa ntchito wofiira, wakuda ndi buluu, etc., kotero solder kukana inki nthawi zambiri amatchedwa wobiriwira mafuta makampani PCB.Ndiwosanjikiza okhazikika oteteza matabwa osindikizidwa, omwe angalepheretse chinyezi, Anti-corrosion, anti-mildew ndi abrasion makina, etc., komanso kuteteza mbali kuti zisawotchedwe kumalo olakwika.

5) Chithandizo chapamwamba

"Pamwamba" monga momwe agwiritsidwira ntchito pano akutanthauza malo olumikizirana pa PCB omwe amapereka kulumikizana kwamagetsi pakati pa zida zamagetsi kapena makina ena ndi mabwalo a PCB, monga malo olumikizirana ndi mapepala kapena zolumikizira.Solderability wa mkuwa wopanda kanthu ndi wabwino kwambiri, koma umakhala wotsekemera komanso wodetsedwa ukakhala ndi mpweya, choncho filimu yoteteza iyenera kuphimbidwa pamwamba pa mkuwa wopanda kanthu.

Common PCB pamwamba mankhwala njira monga lead HASL, lead-free HASL, ❖ kuyanika organic (Organic Solderability Preservatives, OSP), kumizidwa golide, kumizidwa siliva, kumiza malata ndi golide yokutidwa zala, etc. ndi Njira yotsogolera ya HASL yaletsedwa pang'onopang'ono.

6) Makhalidwe

Khalidwe ndi gawo lolemba, pamwamba pa PCB, litha kukhala palibe, ndipo limagwiritsidwa ntchito popereka ndemanga.

Nthawi zambiri, kuti athandizire kukhazikitsa ndi kukonza dera, ma logo ofunikira ndi ma code amasindikizidwa pamwamba ndi pansi pa bolodi losindikizidwa, monga zilembo zamagulu ndi zikhalidwe zodziwika bwino, mawonekedwe agawo ndi ma logo opanga, kupanga. masiku adikira.

Zilembo nthawi zambiri zimasindikizidwa ndi kusindikiza pazenera

Nthawi yotumiza: Mar-11-2023