PCByenziwe ngobuchwepheshe bokuphrinta be-elekthronikhi, ngakho-ke ibizwa ngokuthi ibhodi lesifunda eliphrintiwe.Cishe zonke izinhlobo zezinto zikagesi, kusukela kuma-earphone, amabhethri, okokubala, kuya kumakhompyutha, izinto zokuxhumana, izindiza, amasathelayithi, inqobo nje uma kusetshenziswa izingxenye ze-elekthronikhi ezifana namasekhethi ahlanganisiwe, ama-PCB asetshenziselwa ukuxhumana kukagesi phakathi kwazo.

I-PCB ne-PCBA ama-PCB anezingxenye ezingehlisiwe, i-PCBA (I-Printed Circuit Board Assembly), okungukuthi, ama-PCB ahlome izingxenye ze-elekthronikhi (njengama-chips, izixhumi, izixhasi, ama-capacitor, ama-inductors, njll.).

Umsuka we-PCB

Ngo-1925, uCharles Ducas e-United States (umsunguli wendlela yokwengeza) waphrinta iphethini yesifunda ku-substrate evikelayo, wabe esephumelela ukwenza umqhubi njenge-wiring nge-electroplating.

Ngo-1936, uPaul Eisler wase-Austria (umsunguli wendlela yokususa) waba ngowokuqala ukusebenzisa amabhodi esifunda anyathelisiwe emisakazweni.

Ngo-1943, abantu baseMelika basebenzisa ubuchwepheshe emisakazweni yezempi.Ngo-1948, i-United States yabona ngokusemthethweni ukusungulwa kokusetshenziswa kwezentengiso.

Amabhodi esekethe aphrintiwe asetshenziswe kabanzi kusukela maphakathi nawo-1950, futhi namuhla abusa imboni yezogesi.

Amabhodi esekethe aphrintiwe athuthukile ukusuka kungqimba olulodwa ukuya kuhlangothi olukabili, ungqimba oluningi futhi aguquguqukayo, futhi asalondoloza amathrendi awo okuthuthuka.Ngenxa yokuthuthukiswa okuqhubekayo ekuqondeni kokunemba okuphezulu, ukuminyana okuphezulu nokuthembeka okuphezulu, ukuncishiswa okuqhubekayo kosayizi, ukunciphisa izindleko kanye nokuthuthukiswa kokusebenza, amabhodi wesifunda aphrintiwe asagcina ubungqabavu obuqinile ekuthuthukisweni kwemishini ye-elekthronikhi yesikhathi esizayo.

Izingxoxo zentuthuko yesikhathi esizayo yobuchwepheshe bokukhiqiza ibhodi lesifunda eliphrintiwe ekhaya nakwamanye amazwe ngokuyisisekelo aziguquguquki, okungukuthi, ukuminyana okuphezulu, ukunemba okuphezulu, indawo yokuvula ecolekile, intambo encane, iphimbo elincane, ukwethembeka okuphezulu, ungqimba oluningi, ukudluliselwa kwesivinini esikhulu. , isisindo esilula Ngokuphathelene nokukhiqiza, sithuthuka ngendlela yokwandisa umkhiqizo, ukunciphisa izindleko, ukunciphisa ukungcola, nokujwayela ekukhiqizeni okuhlukahlukene kanye namaqoqo amancane.

Indima ye-PCB

Ngaphambi kokuba ibhodi lesifunda eliphrintiwe livele, ukuxhumana phakathi kwezingxenye ze-elekthronikhi kwakuxhunywe ngokuqondile ngezintambo ukuze kwakhiwe isifunda esiphelele.

Ngemuva kokuthi imishini ye-elekthronikhi yamukele amabhodi wesifunda aphrintiwe, ngenxa yokuvumelana kwamabhodi wesifunda aphrintiwe afanayo, amaphutha ku-wiring manual ayagwenywa.

Ibhodi lesifunda eliphrintiwe linganikeza ukusekelwa kwemishini ukulungisa nokuhlanganisa izingxenye ezihlukahlukene ze-elekthronikhi ezifana namasekhethi ahlanganisiwe, ukuqedela izintambo kanye nokuxhumeka kukagesi noma ukufakwa kukagesi phakathi kwezingxenye ezihlukahlukene ze-elekthronikhi ezifana neziyingi ezihlanganisiwe, futhi zinikeze izici ezidingekayo zikagesi, njengezimpawu Impedance, njll., ingahlinzeka ngemifanekiso yemaski ye-solder ukuze ihlanganiswe ngokuzenzakalelayo, futhi inikeze izinhlamvu zokuhlonza kanye nemifanekiso yokufakwa kwengxenye, ukuhlolwa, nokugcinwa.

Ukuhlukaniswa kwe-PCB

1. Ukuhlukaniswa ngenhloso

Amabhodi esekethe aphrintiwe ezakhamuzi (umthengi): amabhodi esekethe aphrintiwe asetshenziswa kumathoyizi, amakhamera, amathelevishini, izinto zokulalelwayo, omakhalekhukhwini, njll.

Amabhodi esekethe aphrintiwe embonini (izinsiza): amabhodi esekethe aphrintiwe asetshenziswa kwezokuphepha, izimoto, amakhompyutha, imishini yokuxhumana, izinsimbi, njll.

Amabhodi esekethe aphrintiwe ezempi: amabhodi esekethe aphrintiwe asetshenziswa ku-aerospace ne-radar, njll.

2. Ukuhlukaniswa ngohlobo lwe-substrate

Amabhodi wesekethe asekelwe ephepheni: amabhodi wesekethe asekelwe ephepheni asekelwe ephepheni, amabhodi wesekethe asekelwe ephepheni epoxy, njll.

Amabhodi esekethe aphrintiwe asekelwe endwangu yengilazi: amabhodi esekethe enziwe ngendwangu yengilazi ye-epoxy, amabhodi wesekethe enziwe ngengilazi enziwe ngendwangu ye-PTFE, njll.

Ibhodi lesifunda eliphrintiwe le-synthetic fiber: ibhodi lesifunda eliphrintiwe i-epoxy fiber synthetic, njll.

I-Organic film substrate ephrintiwe ibhodi lesifunda: ifilimu ye-nylon ephrintiwe ibhodi lesifunda, njll.

I-Ceramic substrate ephrintiwe amabhodi wesifunda.

Metal core esekelwe ephrintiwe wesekethe amabhodi.

3. Ukuhlukaniswa ngesakhiwo

Ngokusho kwesakhiwo, amabhodi wesifunda aphrintiwe angahlukaniswa abe amabhodi wesifunda aphrintiwe aqinile, amabhodi wesifunda aphrintiwe aguquguqukayo kanye namabhodi wesifunda aphrintiwe aqinile.

4. Ihlukaniswa ngokwenani lezendlalelo

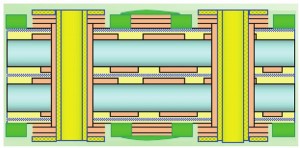

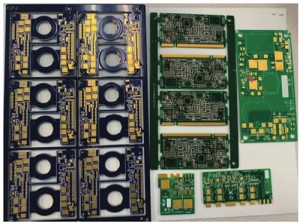

Ngokusho kwenani lezendlalelo, amabhodi esekethe aphrintiwe angahlukaniswa abe amabhodi anohlangothi olulodwa, amabhodi anezinhlangothi ezimbili, amabhodi anezingqimba eziningi kanye namabhodi e-HDI (amabhodi axhumano aphezulu).

1) Uhlangothi olulodwa

Ibhodi elinohlangothi olulodwa libhekisela ebhodini lesifunda elinezintambo ohlangothini olulodwa kuphela (uhlangothi lwe-soldering) lwebhodi lesifunda, futhi zonke izingxenye, amalebula ezingxenye kanye namalebula ombhalo abekwe ngakolunye uhlangothi (uhlangothi lwengxenye).

Isici esikhulu kunazo zonke sephaneli yohlangothi olulodwa yintengo yalo ephansi kanye nenqubo yokukhiqiza elula.Kodwa-ke, njengoba i-wiring ingenziwa endaweni eyodwa kuphela, i-wiring inzima kakhulu, futhi i-wiring ijwayele ukwehluleka, ngakho-ke ifaneleka kuphela kwezinye izifunda ezilula.

2) Izinhlangothi ezimbili

Ibhodi elinamaceleni amabili lifakwe izintambo ezinhlangothini zombili zebhodi le-insulating, uhlangothi olulodwa lusetshenziswa njengesendlalelo esiphezulu, kanti olunye uhlangothi lusetshenziswa njengesendlalelo esingezansi.Izendlalelo ezingaphezulu nezingezansi zixhunywe ngogesi nge-vias.

Ngokuvamile, izingxenye ebhodini elinezingqimba ezimbili zibekwe phezulu;Nokho, ngezinye izikhathi izingxenye zingafakwa kuzo zombili izingqimba ukuze kuncishiswe ubukhulu bebhodi.Ibhodi elinezingqimba ezimbili libonakala ngentengo emaphakathi kanye nezintambo ezilula.Iwuhlobo olusetshenziswa kakhulu kumabhodi esekethe ajwayelekile.

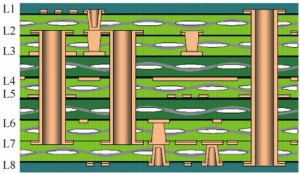

3) Ibhodi lezendlalelo eziningi

Amabhodi esekethe aphrintiwe anezendlalelo ezingaphezu kwezimbili abizwa ngokuhlanganyela ngokuthi amabhodi ezendlalelo eziningi.

4) Ibhodi le-HDI

Ibhodi le-HDI liyibhodi lesifunda elinomthamo omkhulu wokusabalalisa wesekethe lisebenzisa ubuchwepheshe bembobo egqitshwe i-micro-blind.

Isakhiwo se-PCB

I-PCB yakhiwa ikakhulukazi ama-laminates agqoke ithusi (I-Copper Clad Laminates, i-CCL), i-prepreg (ishidi le-PP), i-foil yethusi (i-Copper Foil), imaski ye-solder (eyaziwa nangokuthi imaski ye-solder) (I-Solder Mask).Ngesikhathi esifanayo, ukuze uvikele i-foil yethusi eveziwe ebusweni futhi uqinisekise umphumela we-welding, kuyadingeka futhi ukwenza ukwelashwa okungaphezulu ku-PCB, futhi ngezinye izikhathi kuphinde kumakwe ngezinhlamvu.

1) I-Copper Clad Laminate

I-Copper-clad laminate (CCL), ebizwa ngokuthi i-copper-clad laminate noma i-copper-clad laminate, iyinto eyisisekelo yokukhiqiza amabhodi esekethe aphrintiwe.Yakhiwa ungqimba lwe-dielectric (i-resin, i-glass fiber) kanye nomqhubi we-high-purity conductor (i-foil yethusi).yakhiwe ngezinto ezihlanganisiwe.

Kwaze kwafika ngo-1960 lapho abakhiqizi abangochwepheshe basebenzisa ucwecwe lwethusi lwe-formaldehyde resin njengesisekelo sokwenza ama-PCB anohlangothi olulodwa, futhi bawafaka emakethe yabadlali bamarekhodi, abaqopha amatheyipu, abaqopha amavidiyo, njll. Kamuva, ngenxa yokukhuphuka kwamarekhodi aphindwe kabili. -Ubuchwepheshe bokukhiqiza i-copper plating obuhlangene ngembobo, ukumelana nokushisa, usayizi Ama-substrates engilazi e-epoxy aqinile asetshenziswe kabanzi kuze kube manje.Namuhla, i-FR4, FR1, CEM3, amapuleti e-ceramic namapuleti e-Teflon asetshenziswa kabanzi.

Njengamanje, i-PCB esetshenziswa kabanzi eyenziwe ngendlela yokuqopha iwukuqopha ngokukhetha ebhodini elinezingubo zethusi ukuze kutholwe iphethini yesifunda edingekayo.I-laminate ye-copper clad ihlinzeka ngokuyinhloko imisebenzi emithathu ye-conduction, insulation kanye nokwesekwa kulo lonke ibhodi lesifunda eliphrintiwe.Ukusebenza, ikhwalithi kanye nezindleko zokukhiqiza zamabhodi esekethe aphrintiwe kuncike kakhulu kuma-laminates enziwe ngethusi

2) Prepreg

I-Prepreg, eyaziwa nangokuthi ishidi le-PP, ingenye yezinto ezibalulekile ekukhiqizeni amabhodi amaningi.Ikakhulukazi yakhiwe nge-resin kanye nezinto zokuqinisa.Izinto zokuqinisa zihlukaniswe ngendwangu yengilazi ye-fiber (okubhekiselwa kuyo njengendwangu yengilazi), isisekelo sephepha nezinto eziyinhlanganisela.

Iningi lama-prepregs (amashidi okunamathisela) asetshenziswa ekukhiqizeni amabhodi wesifunda aphrintiwe we-multilayer asebenzisa indwangu yengilazi njengento yokuqinisa.Indwangu yeshidi elincanyana elenziwe ngokufaka indwangu yengilazi ephathwayo ngeglue ye-resin, bese ibhakwa ngaphambili ngokwelashwa okushisa ibizwa ngokuthi i-prepreg.Ama-prepregs athambeka ngaphansi kokushisa nengcindezi futhi aqinise lapho epholile.

Njengoba inani lezintambo zeyunithi ngayinye ubude bendwangu yengilazi ku-wap ne-weft tinkhombandlela lihlukile, kufanele kuqashelwe izikhombisi-ndlela ze-warp ne-weft ye-prepreg lapho usika.Ngokuvamile, isiqondiso se-warp (isiqondiso lapho indwangu yengilazi igoqwe khona) ikhethwa njengesiqondiso esifushane sebhodi lokukhiqiza, futhi isiqondiso se-weft Isiqondiso sohlangothi olude lwebhodi lokukhiqiza ukuqinisekisa ukuvuleka kwebhodi lokukhiqiza. indawo yebhodi futhi ivimbele ibhodi lokukhiqiza ukuthi lingasonteki futhi likhubazekile ngemva kokushisisa.

3) I-foil yethusi

Ucwecwe lwethusi lucwecwe lwensimbi oluncane, oluqhubekayo olufakwe kungqimba oluyisisekelo lwebhodi lesifunda.Njengomqhubi we-PCB, iboshelwa kalula kungqimba lwe-insulating futhi iqoshwe ukwenza iphethini yesifunda.

Izindwangu zethusi ezivamile zezimboni zingahlukaniswa zibe izigaba ezimbili: ucwecwe lwethusi olugoqiwe (ucwecwe lwethusi lwe-RA) kanye nocwecwe lwethusi lwe-electrolytic (icwecwe lethusi le-ED):

Ucwecwe lwethusi olugoqiwe lune-ductility enhle nezinye izici, futhi luwucwecwe lwethusi olusetshenziswa ekuqaleni kwenqubo yebhodi elithambile;

I-Electrolytic copper foil inenzuzo yezindleko eziphansi zokukhiqiza kune-foil yethusi egoqiwe

4) Imaski ye-solder

I-solder resist layer ibhekisela engxenyeni yebhodi lesifunda eliphrintiwe elinoyinki wokumelana ne-solder.

I-Solder resist inki ngokuvamile iluhlaza, futhi abambalwa basebenzisa obomvu, omnyama noluhlaza okwesibhakabhaka, njll., ngakho-ke uyinki yokuphikisa i-solder uvame ukubizwa ngokuthi amafutha aluhlaza embonini ye-PCB.Kuwungqimba oluhlala njalo oluvikelayo lwamabhodi esekethe aphrintiwe, olungavimbela umswakama, i-Anti-corrosion, i-anti-mildew kanye nokuhuzuka komshini, njll., kodwa futhi kuvimbele izingxenye ukuthi zishiselwe ezindaweni ezingalungile.

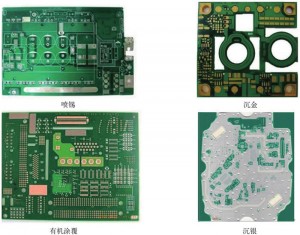

5) Ukwelashwa kwendawo

“Indawo engaphezulu” njengoba isetshenziswe lapha ibhekisela ezindaweni zokuxhuma ku-PCB ezihlinzeka ngoxhumano lukagesi phakathi kwezingxenye ze-elekthronikhi noma amanye amasistimu namasekhethi aku-PCB, njengendawo yokuxhumana yamaphedi noma ukuxhumana.I-solderability yethusi engenalutho ngokwayo inhle kakhulu, kodwa i-oxidized kalula futhi ingcolile lapho ivuliwe emoyeni, ngakho-ke ifilimu yokuzivikela kufanele ihlanganiswe ebusweni bethusi elingenalutho.

Izinqubo ezijwayelekile zokwelashwa kwe-PCB ebusweni zifaka i-HASL eholayo, i-HASL engenamthofu, i-organic coating (Organic Solderability Preservatives, OSP), igolide lokucwiliswa, isiliva lokucwiliswa, ithini lokucwiliswa kanye neminwe yegolide, njll. Ngokuthuthuka okuqhubekayo kwemithetho yokuvikela imvelo, kukhona Inqubo ye-HASL eholayo ivinjelwe kancane kancane.

6) Izinhlamvu

Uhlamvu yisendlalelo sombhalo, phezu kwesendlalelo esiphezulu se-PCB, singaba singekho, futhi ngokuvamile sisetshenziselwa ukuphawula.

Imvamisa, ukuze kube lula ukufakwa nokugcinwa kwesekethe, amaphethini elogo adingekayo namakhodi ombhalo aphrintwa endaweni engaphezulu nephansi yebhodi ephrintiwe, njengamalebula ezingxenye namanani okuzisholo, ukwakheka kohlaka lwengxenye namalogo womkhiqizi, ukukhiqizwa. izinsuku ukulinda.

Izinhlamvu zivame ukuphrintwa ngokuphrinta isikrini

Isikhathi sokuthumela: Mar-11-2023