PCBinogadzirwa nemagetsi ekudhinda tekinoroji, saka inonzi yakadhindwa redunhu board.Anenge ese marudzi ese emidziyo yemagetsi, kubva munzeve, mabhatiri, macalculator, kumakomputa, midziyo yekutaurirana, ndege, satellite, chero zvinhu zvemagetsi zvakaita semasekete akasanganiswa achishandiswa, maPCB anoshandiswa pakubatanidza magetsi pakati pavo.

PCB nePCBA maPCB ane zvidimbu zvisina kusimudzwa, PCBA (Printed Circuit Board Assembly), kureva, maPCB akashongedzerwa nezvinhu zvemagetsi (senge machipisi, zvinobatanidza, resistors, capacitors, inductors, nezvimwewo).

Kwakabva PCB

Muna 1925, Charles Ducas muUnited States (muvambi wenzira yekuwedzera) akadhinda dunhu repateni pane inodzivirira substrate, ndokuzobudirira kugadzira conductor se wiring ne electroplating.

Muna 1936, muAustria Paul Eisler (muvambi wenzira yekubvisa) ndiye akatanga kushandisa mabhodhi edunhu akadhindwa mumaredhiyo.

Muna 1943, vanhu vekuAmerica vakashandisa tekinoroji kumaredhiyo emauto.Muna 1948, United States yakabvuma zviri pamutemo kugadzirwa kwekutengesa.

Mabhodhi edunhu akadhindwa akangoshandiswa zvakanyanya kubva pakati pemakore ekuma1950, uye nhasi anotonga indasitiri yemagetsi.

Mabhodhi edunhu akadhindwa akagadzirwa kubva kune imwe-layer kuenda kune kaviri-mativi, akawanda-layer uye anochinjika, uye achiri kuchengetedza iwo ega ebudiriro maitiro.Nekuda kwekuenderera mberi kwekusimudzira mukutungamira kwehupamhi hwepamusoro, huwandu hwepamusoro uye kuvimbika kwepamusoro, kuenderera kuderedzwa kwehukuru, kuderedzwa kwemutengo uye kuvandudza kwekuita, akadhindwa edunhu mabhodhi achiri kuchengetedza simba rakasimba mukuvandudza kweramangwana midziyo yemagetsi.

Hurukuro pamusoro pemafambiro ekuvandudza kweramangwana rakadhindwa redunhu bhodhi kugadzira tekinoroji kumba nekune dzimwe nyika zvinongoenderana, kureva, kune yakakwira density, yakakwira chaiyo, yakanaka aperture, tambo yakatetepa, diki pitch, yakakwirira kuvimbika, yakawanda-layer, yakakwirira-kumhanya kutumira. , uremu huremu Panyaya yekugadzirwa, iri kukura munzira yekuwedzera kubereka, kuderedza mari, kuderedza kusvibiswa, nekugadzirisa kune zvakasiyana-siyana uye zviduku-madiki kugadzirwa.

Basa rePCB

Pamberi pebhodhi redunhu rakadhindwa risati raonekwa, kuwirirana pakati pezvikamu zvemagetsi zvakabatanidzwa zvakananga newaya kuti dzigadzire dunhu rakazara.

Mushure mekunge zvigadzirwa zvemagetsi zvinotora akadhindwa edunhu mabhodhi, nekuda kwekuenderana kweakadhindwa edunhu mabhodhi, zvikanganiso mumawoko wiring zvinodziviswa.

Bhodhi redunhu rakadhindwa rinogona kupa tsigiro yemagetsi yekugadzirisa uye kuunganidza zvinhu zvakasiyana-siyana zvemagetsi zvakadai semasekete akabatanidzwa, kupedzisa wiring nemagetsi ekubatanidza kana magetsi ekudzivirira pakati pezvinhu zvakasiyana-siyana zvemagetsi zvakadai semasekete akabatanidzwa, uye kupa maitiro emagetsi anodiwa, akadai semaitiro Impedance, nezvimwewo, inogona kupa solder mask giraidhi ye otomatiki soldering, uye inopa ekuzivikanwa mavara uye magirafu ekuisirwa chikamu, kuongorora, uye kugadzirisa.

Classification yePCB

1. Kuronga maererano nechinangwa

Mabhodhi edunhu akadhindwa echivanhu (mutengi): akadhindwa edunhu mabhodhi anoshandiswa mumatoyi, makamera, terevhizheni, midziyo yekuteerera, nharembozha, nezvimwe.

Maindasitiri akadhindwa edunhu mabhodhi (midziyo): akadhindwa edunhu mabhodhi anoshandiswa mukuchengetedzeka, mota, makomputa, michina yekutaurirana, zviridzwa, nezvimwe.

Mauto akadhindwa edunhu mabhodhi: akadhindwa edunhu mabhodhi anoshandiswa mune aerospace uye radar, nezvimwe.

2. Kurongwa nemhando ye substrate

Mapepa-akavakirwa akadhindwa edunhu mabhodhi: phenolic mapepa-akavakirwa akadhindwa edunhu mabhodhi, epoxy pepa-based akadhindwa edunhu mabhodhi, nezvimwe.

Girazi machira-akavakirwa akadhindwa edunhu mabhodhi: epoxy girazi jira-yakavakirwa rakadhindwa redunhu mabhodhi, PTFE girazi jira-yakavakirwa akadhindwa edunhu mabhodhi, nezvimwe.

Synthetic fiber yakadhindwa redunhu bhodhi: epoxy synthetic fiber yakadhindwa redunhu bhodhi, nezvimwe.

Organic firimu substrate yakadhindwa redunhu bhodhi: naironi firimu rakadhindwa redunhu bhodhi, nezvimwe.

Ceramic substrate yakadhindwa mapuranga edunhu.

Metal core based printed circuit boards.

3. Kurongwa nechimiro

Zvinoenderana nechimiro, akadhindwa edunhu mabhodhi anogona kukamurwa kuita akaomesesa akadhindwa edunhu mabhodhi, anochinjika akadhindwa edunhu mabhodhi uye akaomesesa-anoshanduka akadhindwa edunhu mabhodhi.

4. Yakarongedzerwa zvichienderana nehuwandu hwezvikamu

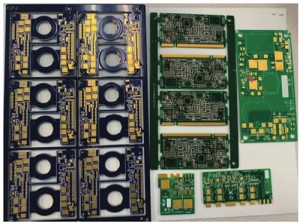

Zvinoenderana nenhamba yezvikamu, mabhodhi edunhu akadhindwa anogona kukamurwa kuita mapuranga ane mativi maviri, maviri-mativi mabhodhi, akawanda-layer mabhodhi uye HDI mabhodhi (yakakwirira-density interconnect board).

1) Single sided

A single-sided board inoreva bhodhi redunhu rine waya kune rimwe divi (soldering side) redunhu bhodhi, uye zvese zvikamu, zvikamu zvinyorwa uye zvinyorwa zvinyorwa zvinoiswa kune rimwe divi (chikamu chechikamu).

Chinhu chikuru pane imwe-sided panel ndiyo yakaderera mutengo uye nyore kugadzira maitiro.Zvisinei, sezvo wiring inogona kungoitwa pane imwe chete, iyo wiring inonyanya kuoma, uye wiring inowanzokundikana, saka inongofanirwa kune mamwe matunhu ari nyore.

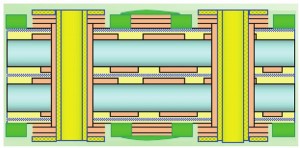

2) Madivi maviri

Bhodhi-yakapetwa kaviri yakasungirirwa kumativi ose e-insulating board, rumwe rutivi runoshandiswa sepamusoro pepamusoro, uye rumwe rutivi runoshandiswa sepasi pasi.Kumusoro uye pasi akaturikidzana akabatanidzwa magetsi kuburikidza vias.

Kazhinji, zvikamu pane maviri-layer board anoiswa pamusoro pepamusoro;zvisinei, dzimwe nguva zvikamu zvinogona kuiswa pazvikamu zviviri kuitira kuderedza ukuru hwebhodhi.Iyo kaviri-layer board inoratidzwa nemutengo wakadzikama uye nyore wiring.Ndiyo mhando inonyanya kushandiswa mumabhodhi edunhu akajairika.

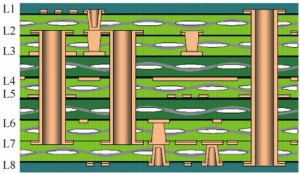

3) Multi-layer board

Mabhodhi edunhu akadhindwa ane anopfuura maviri akaturikidzana akaunganidzwa anonzi mabhodhi akawanda.

4) HDI bhodhi

Iyo HDI bhodhi ibhodhi redunhu rine yakawedzera redunhu kugovera density uchishandisa micro-mapofu yakavigwa gomba tekinoroji.

PCB chimiro

PCB inonyanya kuumbwa nemhangura yakapfeka laminates (Copper Clad Laminates, CCL), prepreg (PP sheet), foil yemhangura (Copper Foil), solder mask (inozivikanwawo se solder mask) (Solder Mask).Panguva imwecheteyo, kuitira kuchengetedza yakafumurwa foil yemhangura pamusoro uye ive nechokwadi chekuita welding, zvinodikanwa zvakare kuita kurapa kwepamusoro paPCB, uye dzimwe nguva inomisikidzwa nemavara.

1) Copper Clad Laminate

Copper-clad laminate (CCL), inonzi mhangura-clad laminate kana copper-clad laminate, ndiyo yakakosha zvinhu pakugadzira akadhindwa edunhu mabhodhi.Inoumbwa ne dielectric layer (resin, girazi fiber) uye yakakwirira-kuchena conductor (copper foil).inoumbwa nezvinhu zvakasanganiswa.

Yakanga isati yasvika muna 1960 apo vagadziri vane hunyanzvi vakashandisa formaldehyde resin copper foil sechinhu chekutanga kugadzira maPCB ane divi rimwe chete, ndokuaisa mumusika wevatambi verekodhi, matepi rekodha, vhidhiyo rekodha, etc. Gare gare, nekuda kwekukwira kwekaviri. -sided kuburikidza-gomba copper plating kugadzira tekinoroji, kupisa kuramba, saizi Yakagadzikana epoxy girazi substrates yakashandiswa zvakanyanya kusvika zvino.Mazuva ano, FR4, FR1, CEM3, mahwendefa eceramic uye Teflon mahwendefa anoshandiswa zvakanyanya.

Parizvino, iyo inonyanya kushandiswa PCB yakagadzirwa ne etching nzira ndeyekusarudza etch pane yemhangura yakapfeka bhodhi kuti uwane inodiwa yedunhu pateni.Iyo copper clad laminate inonyanya kupa mabasa matatu ekuitisa, insulation uye tsigiro pane yese yakadhindwa redunhu board.Kuita, kunaka uye mutengo wekugadzira weakadhindwa edunhu mabhodhi anoenderana zvakanyanya nemhangura yakapfeka laminates

2) Prepreg

Prepreg, inozivikanwawo sePP pepa, chimwe chezvinhu zvikuru mukugadzirwa kwemapuranga akawanda.Iyo inonyanya kuumbwa ne resin uye yekusimbisa zvinhu.Zvinhu zvekusimbisa zvakakamurwa kuita girazi fiber jira (rinonzi jira regirazi), base bepa uye composite zvinhu.

Mazhinji e prepregs (adhesive sheets) anoshandiswa mukugadzira multilayer akadhindwa edunhu mabhodhi anoshandisa girazi jira sechinhu chinosimbisa.Pepa rakatetepa rakagadzirwa nekupfekedza jira regirazi rakagadziriswa neglue resin, uyezve rakabikwa kare nekupisa kurapwa kunonzi prepreg.Prepregs inopfava pasi pekupisa uye kumanikidzwa uye kusimba kana yatonhodzwa.

Sezvo huwandu hwetambo dzeshinda pahurefu hweyuniti yejira regirazi muwarp uye weft nzira dzakasiyana, kutarisisa kunofanirwa kubhadharwa kune warp uye weft nzira dze prepreg kana uchicheka.Kazhinji, iyo warp direction (iyo nzira iyo jira regirazi rinopetwa) inosarudzwa sepfupi yedivi nzira yebhodhi rekugadzira, uye iyo weft kutungamira ndiyo Inotungamira yerutivi rurefu rwebhodhi rekugadzira ndeyekuona kupfava kweiyo. bhodhi pamusoro uye kudzivirira bhodhi rekugadzira kubva pakumonyoroka nekuremara mushure mekupisa.

3) Copper foil

Foil yemhangura isimbi yakatetepa, inoenderera mberi yakaiswa panheyo yedenderedzwa redunhu.Semutyairi wePCB, inosungirirwa zviri nyore kune insulating layer uye yakamisikidzwa kuti iite dunhu redunhu.

Yakajairika maindasitiri emhangura foil anogona kukamurwa kuita mapoka maviri: akakungurutswa mhangura foil (RA copper foil) uye electrolytic copper foil (ED copper foil):

Yakakungurutswa yemhangura foil ine yakanaka ductility uye humwe hunhu, uye ndiyo foil yemhangura inoshandiswa mukutanga nyoro bhodhi process;

Electrolytic copper foil ine mukana weiyo yakaderera mutengo wekugadzira pane yakakungurutswa foil yemhangura

4) Solder mask

Iyo solder resist layer inoreva chikamu chebhodhi rakadhindwa redunhu rine solder resist inki.

Solder kuramba inki inowanzo girini, uye vashoma vanoshandisa tsvuku, nhema uye bhuruu, zvichingodaro, saka solder kuramba inki inowanzonzi mafuta egirini muPCB indasitiri.Iyo inogara inodzivirira yakaturikidzana yeakadhindwa edunhu mapuranga, ayo anogona kudzivirira mwando, Anti-corrosion, anti-mildew uye mechanical abrasion, nezvimwewo, asi zvakare kudzivirira zvikamu kubva kune welded kunzvimbo dzisina kururama.

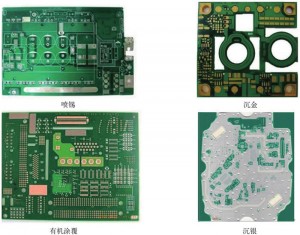

5) Kurapa kwepamusoro

"Surface" sekushandiswa kunoitwa pano inoreva nzvimbo dzekubatanidza paPCB dzinopa kubatanidza kwemagetsi pakati pezvinhu zvemagetsi kana mamwe masisitimu uye maseketi ari paPCB, senge mapoinzi ekubatanidza emapadhi kana ekubatanidza.Iyo solderability yemhangura isina chinhu pachayo yakanaka kwazvo, asi inogadziriswa nyore nyore uye yakasvibiswa kana yaiswa mumhepo, saka firimu rinodzivirira rinofanira kuvharwa pamusoro pemhangura isina chinhu.

Common PCB pamusoro pekurapa maitiro anosanganisira lead HASL, lead-isina HASL, organic coating (Organic Solderability Preservatives, OSP), kunyudza goridhe, kunyudza sirivha, kunyudza tini uye zvigunwe zvakaputirwa negoridhe, etc. Nekuenderera mberi kwekuvandudzwa kwemitemo yekuchengetedza nharaunda, ikoko are Iyo inotungamira HASL maitiro akarambidzwa zvishoma nezvishoma.

6) Vanhu

Hunhu ndiwo mavara echinyorwa, pamusoro pepamusoro pePCB, anogona kunge asipo, uye anowanzo shandiswa pakutaura.

Kazhinji, kuitira kugonesa kuisirwa nekuchengetedza dunhu, iyo inodiwa logo mapatani uye mameseji makodhi anodhindwa pamusoro nepamusoro pepasi pebhodhi rakadhindwa, senge mabhii echikamu uye hunhu hwezita, maumbirwo echikamu uye marogo emugadziri, kugadzirwa. mazuva anomirira.

Mavara anowanzo kudhindwa nescreen printing

Nguva yekutumira: Mar-11-2023