PCBwaxaa lagu sameeyaa tignoolajiyada daabacaadda elegtarooniga ah, sidaas darteed waxaa loogu yeeraa looxa wareegyada daabacan.Ku dhawaad nooc kasta oo qalab elektaroonik ah, oo u dhexeeya sameecadaha, baytariyada, xisaabiyeyaasha, kombuyuutarrada, qalabka isgaarsiinta, diyaaradaha, satalaytka, ilaa iyo inta qaybaha elektiroonigga ah sida wareegyada isku dhafan ee la isticmaalo, PCB-yada waxaa loo isticmaalaa isku xirka korontada ee dhexdooda.

PCB iyo PCBA waa PCBs leh qaybo aan la rakibin, PCBA (Printed Circuit Board Assembly), taas oo ah, PCB-yada ku qalabaysan qaybaha elektarooniga ah (sida chips, connectors, resistors, capacitors, inductors, iwm.).

Asalkii la odhan ah PCB

Sanadkii 1925-kii, Charles Ducas oo ku nool dalka Mareykanka (asal-hayihii habka wax-ku-kordhinta) wuxuu ku daabacay qaab wareeg ah substrate-ka dahaaran, ka dibna wuxuu si guul leh u sameeyay koronto sida xargo iyadoo la isticmaalayo koronto-sameeyaha.

Sannadkii 1936kii, Australiyaanka Paul Eisler (asallaha habka kala-goynta) ayaa ahaa kii ugu horreeyay ee isticmaala looxyada wareegyada daabacan ee raadiyaha.

Sannadkii 1943-kii, dadka Maraykanku waxay adeegsadeen tignoolajiyada raadiyaha militariga.Sannadkii 1948-kii, Maraykanku wuxuu si rasmi ah u aqoonsaday ikhtiraacida isticmaalka ganacsiga.

Looxyada wareegyada daabacan ayaa kaliya si weyn loo isticmaali jiray ilaa bartamihii 1950-meeyadii, maantana waxay xukumaan warshadaha elektiroonigga ah.

Looxyada wareegyada daabacan ayaa ka soo baxay hal-lakab ilaa laba-geesood, lakabyo badan iyo dabacsanaan, walina waxay ilaaliyaan isbeddellada horumarineed ee iyaga u gaar ah.Sababtoo ah horumarinta joogtada ah ee jihada saxda ah ee saxda ah, cufnaanta sare iyo kalsoonida sare, hoos u dhigista joogtada ah ee cabbirka, dhimista kharashka iyo hagaajinta waxqabadka, looxyada wareegyada daabacan ayaa weli ilaalinaya tamarta xooggan ee horumarinta qalabka elektiroonigga ah ee mustaqbalka.

Doodaha ku saabsan isbeddelka horumarinta mustaqbalka ee tignoolajiyada wax soo saarka guddiga daabacaadda daabacan ee guriga iyo dibedda ayaa asal ahaan joogto ah, taas oo ah, cufnaanta sare, saxnaanta sare, daloolka wanaagsan, silig khafiif ah, garoon yar, isku halaynta sare, lakabyo badan, gudbinta xawaaraha sare , Miisaanka fudud Xagga wax-soo-saarka, waxa uu ku horumarayaa jihada kordhinta wax-soo-saarka, dhimista kharashka, yaraynta wasakhowga, iyo la qabsiga wax-soo-saarka dufcadaha kala duwan iyo yar yar.

Doorka PCB

Ka hor inta uusan soo bixin guddiga wareegga daabacan, isku xirka qaybaha elektiroonigga ah ayaa si toos ah loogu xiray fiilooyinka si loo sameeyo wareeg dhamaystiran.

Ka dib markii qalabka elektarooniga ah uu qaato looxyada wareegyada daabacan, sababtoo ah joogteynta looxyada wareegyada daabacan ee la midka ah, khaladaadka fiilooyinka gacanta ayaa laga fogaadaa.

Guddiga wareegga daabacan ayaa ku siin kara taageero farsamo si loo hagaajiyo loona ururiyo qaybaha kala duwan ee elektiroonigga ah sida wareegyada isku dhafan, dhamaystiraan fiilooyinka iyo isku xirka korantada ama dahaarka korantada ee u dhexeeya qaybaha kala duwan ee elektiroonigga ah sida wareegyada isku dhafan, oo bixiya sifooyinka korantada ee loo baahan yahay, sida sifooyinka Impedance. iwm., waxay ku siin karaan garaafyada maaskaro alxanka si toos ah alxanka, oo waxay ku siin karaan jilayaasha aqoonsiga iyo garaafyada gelinta, kormeerka, iyo dayactirka.

Kala soocidda PCB

1. Kala-saar ujeeddo

Looxyada wareegyada daabacan ee madaniga ah (macmiilka): looxyada wareegyada daabacan ee loo isticmaalo alaabta lagu ciyaaro, kamaradaha, telefishinada, qalabka maqalka, moobilada, iwm.

Looxyada wareegyada daabacan ee warshadaha (qalabka): looxyada wareegyada daabacan ee loo isticmaalo amniga, baabuurta, kumbuyuutarka, mishiinada isgaarsiinta, aaladaha, iwm.

Looxyada wareegyada daabacan ee militariga: looxyada wareegyada daabacan ee loo isticmaalo hawada iyo raadaarka, iwm.

2. Kala soocida nooca substrate

Looxyada wareegyada daabacan ee warqad ku saleysan: looxyada wareegyada daabacan ee warqadaha phenolic, warqad epoxy-ku-saleysan oo daabacan, iwm.

Looxyada wareegyada daabacan ee maro-ku-saleysan: epoxy galaas maro daabacan oo daabacan, looxyada wareegyada daabacan ee PTFE, iwm.

looxa wareegga daabacan ee fiber synthetic: epoxy synthetic fiber-ka daabacan guddiga wareegga, iwm.

Substrate filim dabiici ah oo daabacan guddiga wareegga: filimka nylon ee daabacan guddiga wareegga, iwm.

Substrate dhoobada daabacan looxyada wareegga.

Looxyada wareegga daabacan ee xudunta u ah birta.

3. Kala soocida qaab dhismeed

Marka loo eego qaab-dhismeedka, looxyada daabacan ee daabacan waxaa loo qaybin karaa looxyo wareeg ah oo daabacan, dhejisyo daabacan oo dabacsan iyo kuwo daabacan oo dabacsan

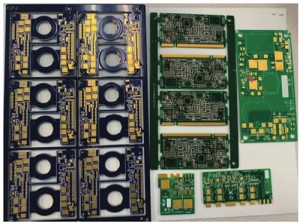

4. Loo kala saaray iyadoo loo eegayo tirada lakabyada

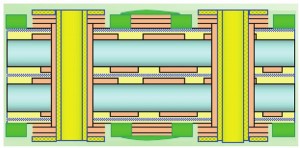

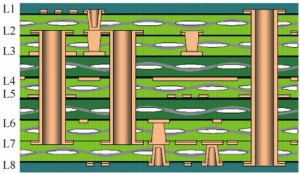

Marka loo eego tirada lakabyada, looxyada wareegyada daabacan waxaa loo qaybin karaa looxyo hal dhinac ah, looxyo laba-dhinac ah, looxyo lakabyo badan iyo HDI (looxyo isku xiran oo cufan oo sarreeya).

1) Hal dhinac

Looxa hal dhinac ah waxa loola jeedaa guddi wareeg ah oo ku xidhan hal dhinac oo keliya (dhinaca wax iibinta) ee looxa wareegga, dhammaan qaybaha, sumadaha qaybaha iyo calaamadaha qoraalka ayaa la dhigayaa dhinaca kale (dhinaca qaybaha).

Muuqaalka ugu weyn ee guddiga hal-dhinac ah waa qiimaha hooseeya iyo habka wax soo saarka ee fudud.Si kastaba ha noqotee, maadaama fiilooyinka lagu fulin karo hal dusha kaliya, fiilooyinka ayaa aad u adag, fiilooyinka waxay u nugul yihiin fashilka, sidaas darteed waxay ku habboon tahay oo kaliya wareegyada fudud qaarkood.

2) Labada dhinac

Looxa laba-geesoodka ah ayaa lagu xiraa labada dhinac ee looxa dahaarka, hal dhinac ayaa loo isticmaalaa sida lakabka sare, dhinaca kalena waxaa loo isticmaalaa sida lakabka hoose.Lakabyada sare iyo kuwa hoose waxay ku xiran yihiin koronto iyada oo loo marayo vias.

Caadi ahaan, qaybo ka mid ah guddi laba lakab ah ayaa la dhigayaa lakabka sare;si kastaba ha ahaatee, mararka qaarkood qaybo ayaa lagu dhejin karaa labada lakab si loo yareeyo xajmiga looxa.Guddiga laba-lakabka ah waxaa lagu gartaa qiimaha dhexdhexaadka ah iyo fiilooyinka sahlan.Waa nooca ugu badan ee loo isticmaalo looxyada wareegga caadiga ah.

3) Loox-lakab badan

Looxyada wareegyada daabacan oo leh wax ka badan laba lakab ayaa si wada jir ah loogu tilmaamaa looxyo badan.

4) guddiga HDI

Guddiga HDI waa guddi wareeg ah oo leh cufnaanta qaybinta wareegga xad aad u sarreeya iyadoo la adeegsanayo tignoolajiyada daloolka aasan ee yar-yar.

Qaab dhismeedka PCB

PCB waxay inta badan ka kooban tahay laminates-copper clad (Copper Clad Laminates, CCL), prepreg (PP sheet), foil copper (Copper Foil), maaskarada alxanka (sidoo kale loo yaqaano maaskarada alxanka) (Maaskarada Alxanka).Isla mar ahaantaana, si loo ilaaliyo foornada naxaasta ah ee dusha sare leh oo loo hubiyo saameynta alxanka, sidoo kale waa lagama maarmaan in lagu sameeyo daaweynta dusha PCB, mararka qaarkoodna sidoo kale waxaa lagu calaamadeeyaa jilayaal.

1) Copper Clad Laminate

Laminate Copper-clad Laminate (CCL), oo loo yaqaan laminate naxaas ah ama laminate naxaas ah, ayaa ah alaabta aasaasiga ah ee soo saarista looxyada wareegyada daabacan.Waxay ka kooban tahay lakabka dielectric (resin, fiber galaas) iyo kaari saafi ah oo sarreeya (foil naxaas ah).oo ka kooban walxo isku dhafan.

Ma ahayn ilaa 1960-kii in soo-saareyaasha xirfadlayaasha ah ay isticmaaleen foornada naxaasta ah ee formaldehyde sida walxaha aasaasiga ah si ay u sameeyaan PCB-yada hal-dhinac ah, oo ay geliyaan suuqa ciyaartoyda rikoodhada, duubista cajaladaha, cajaladaha fiidiyowga, iwm. Later, sababtoo ah kor u kaca labanlaab. Tignoolajiyada wax-soo-saarka naxaasta-daloolin-dhinac-daloolin ah, iska caabbinta kulaylka, cabbirka muraayadaha galaas ee Epoxy deggan ayaa si ballaaran loo isticmaalay ilaa hadda.Maalmahan, FR4, FR1, CEM3, taarikada dhoobada iyo taarikada Teflon ayaa si weyn loo isticmaalaa.

Waqtigan xaadirka ah, PCB-ga aadka loo isticmaalo ee lagu sameeyo habka etching waa in si xushmad leh loogu dhejiyo looxa koodhka ah si loo helo qaabka wareegga loo baahan yahay.Laminate-ka maxaasta ah ayaa inta badan bixiya saddex hawlood oo kaxaynta, dahaarka iyo taageerada dhammaan looxa wareegyada daabacan.Waxqabadka, tayada iyo kharashka wax soo saarka ee looxyada wareegyada daabacan waxay ku xiran tahay xad weyn oo ku saabsan laminatesyada naxaasta ah

2) Prepreg

Prepreg, oo sidoo kale loo yaqaan xaashida PP, waa mid ka mid ah agabyada ugu muhiimsan ee wax soo saarka looxyada badan.Waxay inta badan ka kooban tahay xabagta iyo agabka xoojinta.Qalabka xoojinta waxaa loo qaybiyaa maro fiber galaas ah (oo loo yaqaan maro dhalada ah), saldhigga warqadda iyo walxaha isku dhafan.

Inta badan prepregs (xabagyada xabagta) ee loo isticmaalo soo saarista looxyada daabacan ee lakabyada badan waxay isticmaalaan maro dhalada ah walxo xoojin ah.Walaxda xaashida dhuuban ee lagu sameeyay marada dhalada ah ee lagu daaweeyay xabagta xabagta, ka dibna lagu dubay daawaynta kulaylka waxaa loo yaqaan prepreg.Prepregs waxay ku jilcisaa kulaylka iyo cadaadiska waxayna xoojisaa marka la qaboojiyo.

Maaddaama tirada dunta dunta ee dhererka cutubka dhererka muraayadda ee jihooyinka qulqulka iyo qulqulka ay ka duwan yihiin, fiiro gaar ah waa in la bixiyaa jihada qulqulka iyo jilbaha ee prepreg marka la jarayo.Guud ahaan, jihada warp (jihada ay marada galaaska la duuduubo) waxaa loo xushay jihada gaaban ee guddiga wax soo saarka, iyo jihada weft waa jihada dhinaca dheer ee guddiga wax soo saarka waa in la hubiyo flatness ee dusha sare ee looxa oo ka ilaali guddiga wax-soo-saarka inuu qallooco oo uu qalloocdo ka dib marka la kululeeyo.

3) bireed naxaas ah

Caleenta Copper waa bir dhuuban, bir ah oo joogto ah oo lagu shubay lakabka hoose ee looxa wareegga.Kaari ahaan PCB-ga, si fudud ayaa loogu xidhaa lakabka dahaadhka ah oo loo xardhay si loo sameeyo qaab wareeg ah.

Foornada naxaasta ee warshadaha ee caadiga ah waxa loo qaybin karaa laba qaybood: foil naxaas ah oo duuban (RA copper foil) iyo foil copper electrolytic (ED copper foil):

Foornada naxaasta ah ee duuban waxay leedahay ductility wanaagsan iyo sifooyin kale, waana foornada naxaasta ah ee loo isticmaalo geeddi-socodka guddiga jilicsan ee hore;

Foornada naxaasta ah ee Electrolytic waxay faa'iido u leedahay kharashka wax soo saarka ee ka hooseeya foornada naxaasta duuban

4) Maaskarada Alxanka

Lakabka iska caabinta alxanka waxa loola jeedaa qaybta looxa wareegga daabacan ee leh khad caabbinta alxanka.

Khadka iska caabinta alxanka badanaa waa cagaar, qaarna waxay isticmaalaan casaan, madow iyo buluug, iwm.Waa lakabka ilaalinta joogtada ah ee looxyada wareegyada daabacan, kaas oo ka hortagi kara qoyaanka, Ka-hortagga daxalka, caarada-ka-hortagga iyo xoqidda farsamada, iwm, laakiin sidoo kale waxay ka hortagtaa qaybaha in lagu dhufto meelo aan sax ahayn.

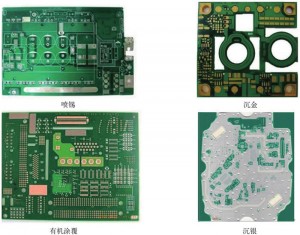

5) Daaweynta dusha sare

"Surface" sida halkan lagu isticmaalo waxaa loola jeedaa dhibcaha isku xirka PCB ee bixiya xiriirka koronto ee ka dhexeeya qaybaha elektaroonigga ah ama nidaamyada kale iyo wareegyada PCB-ga, sida goobaha isku xirka suufka ama xiriirka xiriirka.Alxanka naxaasta qaawan lafteedu aad bay u fiican tahay, laakiin si sahal ah ayay oksaydhisku u wasakhaysan tahay marka ay hawada soo gasho, markaa waa in filim difaac ah lagu daboolaa dusha naxaasta qaawan.

Nidaamyada daaweynta dusha PCB ee caadiga ah waxaa ka mid ah HASL rasaas, HASL-free-lead, daahan organic (Organic Solderability Preservatives, OSP), dahab immersion, qalin immersion, daasadda immersion iyo faraha dahabka-daray, iwm Iyadoo horumarinta joogtada ah ee xeerarka ilaalinta deegaanka, halkaas Habka hogaanka HASL si tartiib tartiib ah ayaa loo mamnuucay.

6) Jilayaasha

Dabeecaddu waa lakabka qoraalka, lakabka sare ee PCB-ga, waa uu maqnaan karaa, waxaana guud ahaan loo isticmaalaa faallooyinka.

Caadi ahaan, si loo fududeeyo rakibidda iyo dayactirka wareegga, qaababka calaamadda loo baahan yahay iyo code-yada qoraalka ayaa lagu daabacaa dusha sare iyo hoose ee looxa daabacan, sida calaamadaha qaybaha iyo qiyamka magaca, qaababka qeexida qaybaha iyo calaamadaha soo saaraha, wax soo saarka taariikhaha sugi.

Calaamadaha waxaa badanaa lagu daabacaa daabacaadda shaashadda

Waqtiga boostada: Mar-11-2023