PCBhana ʻia e ka ʻenehana paʻi uila, no laila ua kapa ʻia ʻo ia ka papa kaapuni paʻi.Aneane o kela a me keia ano o na lako uila, mai ka pepeiao pepeiao, ka pila, calculators, a hiki i ka lolouila, lako kamaʻilio, mokulele, satellite, ke hoʻohana ʻia nā ʻāpana uila e like me nā kaapuni hoʻohui, hoʻohana ʻia nā PCB no ka pilina uila ma waena o lākou.

ʻO ka PCB a me ka PCBA he mau PCB me nā mea i hoʻopaʻa ʻole ʻia, PCBA (Printed Circuit Board Assembly), ʻo ia hoʻi, nā PCB i hoʻolako ʻia me nā ʻāpana uila (e like me nā chips, nā mea hoʻohui, nā resistors, capacitors, inductors, etc.).

Ke kumu o ka PCB

I ka makahiki 1925, ua paʻi ʻo Charles Ducas ma ʻAmelika Hui Pū ʻIa (ka mea nāna i hoʻokumu i ke ʻano hoʻohui) i kahi ʻano kaapuni ma kahi substrate insulating, a laila hana maikaʻi ʻo ia i ke alakaʻi ma ke ʻano he uwila ma ka electroplating.

I ka makahiki 1936, ʻo ka Austrian Paul Eisler (ka mea nāna i hoʻokumu i ke ʻano subtractive) ʻo ia ka mea mua i hoʻohana i nā papa kaapuni paʻi i nā lekiō.

I ka makahiki 1943, ua hoʻohana nā ʻAmelika i ka ʻenehana i nā lekiō koa.I ka makahiki 1948, ua ʻae ʻo ʻAmelika Hui Pū ʻIa i ka mea hou no ka hoʻohana pāʻoihana.

Ua hoʻohana nui ʻia nā papa kaapuni i paʻi ʻia mai ka waena o 1950s, a i kēia lā ua lanakila lākou i ka ʻoihana uila.

Ua hoʻomohala ʻia nā papa kaapuni i paʻi ʻia mai ka papa hoʻokahi a i ʻelua ʻaoʻao, multi-layer a maʻalahi, a mālama mau i kā lākou mau ʻano hoʻomohala.Ma muli o ka hoʻomau mau ʻana i ke kuhikuhi o ka precision kiʻekiʻe, kiʻekiʻe kiʻekiʻe a me ka hilinaʻi kiʻekiʻe, ka hoʻemi mau ʻana i ka nui, ka hoʻemi ʻana i ke kumukūʻai a me ka hoʻomaikaʻi ʻana i ka hana, mālama mau nā papa kaapuni paʻi i ka ikaika i ka hoʻomohala ʻana i nā lako uila e hiki mai ana.

Kūlike nā kūkākūkā e pili ana i ka wā e hiki mai ana o ka ʻenehana hana papa kaapuni paʻi ma ka home a ma waho, ʻo ia hoʻi, i ke kiʻekiʻe kiʻekiʻe, kiʻekiʻe kiʻekiʻe, aperture maikaʻi, uea lahilahi, pitch liʻiliʻi, hilinaʻi kiʻekiʻe, multi-layer, high-speed transmission. , ke kaumaha māmā Ma keʻano o ka hanaʻana, ke ulu nei ia ma ke kuhikuhi o ka hoʻonuiʻana i ka huahana, ka ho'ēmiʻana i nā kumukūʻai, ka hoʻohaʻahaʻaʻana i ka haumia, a me ka hoʻololiʻana i nāʻano likeʻole a me nā mea liʻiliʻi.

ʻO ke kuleana o PCB

Ma mua o ka ʻike ʻia ʻana o ka papa kaapuni i paʻi ʻia, ua hoʻopili pololei ʻia ka pilina ma waena o nā mea uila e nā uwea e hana i kahi kaapuni piha.

Ma hope o ka hoʻohana ʻana o nā lako uila i nā papa kaapuni i paʻi ʻia, ma muli o ke kūlike o nā papa kaapuni paʻi like, pale ʻia nā hewa i ka wili lima.

Hiki i ka papa kaapuni paʻi ke hāʻawi i ke kākoʻo mechanical no ka hoʻoponopono ʻana a me ka hoʻohui ʻana i nā ʻāpana uila like ʻole e like me nā kaʻa i hoʻohui ʻia, e hoʻopau i ka uwila a me ka hoʻopili uila a i ʻole ka insulation uila ma waena o nā mea uila like ʻole e like me nā ʻāpana uila, a hāʻawi i nā ʻano uila e pono ai, e like me nā hiʻohiʻona Impedance, etc., hiki ke hāʻawi i nā kiʻi solder mask no ke kūʻai aku ʻana, a hāʻawi i nā kiʻi ʻike a me nā kiʻi no ka hoʻokomo ʻana, ka nānā ʻana, a me ka mālama ʻana.

Hoʻokaʻawale o PCB

1. Hoʻokaʻawale ʻia ma ke kumu

Nā papa kaapuni paʻi kīwila (mea kūʻai aku): nā papa kaapuni paʻi i hoʻohana ʻia i nā mea pāʻani, nā pahupaʻikiʻi, nā kīwī, nā lako leo, nā kelepona paʻalima, a pēlā aku.

ʻO nā papa kaapuni paʻi ʻoihana (nā lako): nā papa kaapuni paʻi i hoʻohana ʻia i ka palekana, nā kaʻa, nā kamepiula, nā mīkini kamaʻilio, nā mea kani, etc.

Nā papa kaapuni paʻi koa: nā papa kaapuni paʻi i hoʻohana ʻia i ka aerospace a me ka radar, etc.

2. Hoʻokaʻawale ʻia e ke ʻano substrate

Nā papa kaapuni paʻi paʻi pepa: nā papa kaapuni paʻi paʻi pepa phenolic, nā papa kaapuni paʻi pepa epoxy, etc.

Nā papa kaapuni i paʻi ʻia i ka lole aniani: nā papa kaapuni paʻi kiʻi aniani epoxy, nā papa kaapuni paʻi kiʻi aniani PTFE, etc.

ʻO ka papa kaapuni paʻi kiʻi synthetic: epoxy synthetic fiber paʻi ʻia ka papa kaapuni, etc.

Papa kaapuni paʻi kiʻiʻoniʻoni organik: papa kaapuni paʻi kiʻiʻoniʻoni naylon, etc.

ʻO nā papa kaapuni paʻi paʻi seramika.

Nā papa kaapuni i paʻi ʻia ma ke kumu metala.

3. Hoʻokaʻawale ʻia ma ke ʻano

E like me ka hoʻolālā, hiki ke hoʻokaʻawale ʻia nā papa kaapuni i paʻi ʻia i nā papa kaapuni paʻi paʻi paʻi, nā papa kaapuni paʻi maʻalahi a me nā papa kaapuni paʻi paʻi.

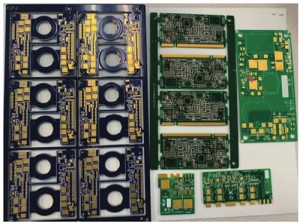

4. Hoʻokaʻawale ʻia e like me ka helu o nā papa

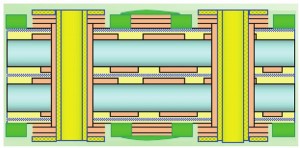

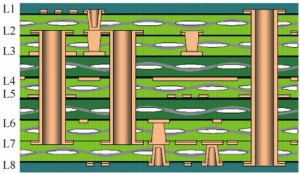

E like me ka helu o nā papa, hiki ke hoʻokaʻawale ʻia nā papa kaapuni i paʻi ʻia i nā papa ʻaoʻao hoʻokahi, nā papa ʻelua ʻaoʻao, nā papa multi-layer a me nā papa HDI (nā papa pili kiʻekiʻe kiʻekiʻe).

1) ʻaoʻao hoʻokahi

ʻO ka papa ʻaoʻao hoʻokahi e pili ana i kahi papa kaapuni i hoʻopaʻa ʻia ma ka ʻaoʻao hoʻokahi wale nō (ʻaoʻao kūʻai) o ka papa kaapuni, a kau ʻia nā ʻāpana āpau, nā lepili ʻāpana a me nā lepili kikokikona ma kēlā ʻaoʻao (ʻaoʻao hapa).

ʻO ka hiʻohiʻona nui loa o ka papa hoʻokahi ʻaoʻao kona kumu kūʻai haʻahaʻa a me ke kaʻina hana maʻalahi.Eia nō naʻe, no ka mea hiki ke hoʻokō ʻia ka uea ma luna o ka ʻili hoʻokahi, ʻoi aku ka paʻakikī o ka uea, a ʻoi aku ka maikaʻi o ka uwila, no laila kūpono wale ia no kekahi mau kaapuni maʻalahi.

2) ʻaoʻao ʻelua

Hoʻohana ʻia ka papa ʻaoʻao ʻelua ma nā ʻaoʻao ʻelua o ka papa insulating, hoʻohana ʻia kekahi ʻaoʻao e like me ka papa luna, a ʻo kekahi ʻaoʻao e like me ka papa lalo.Hoʻopili uila ʻia ka papa luna a me lalo ma o vias.

ʻO ka mea maʻamau, kau ʻia nā ʻāpana ma kahi papa ʻelua ma luna o ka papa luna;akā naʻe, i kekahi manawa hiki ke kau ʻia nā ʻāpana ma nā papa ʻelua i mea e hōʻemi ai i ka nui o ka papa.Hōʻike ʻia ka papa pālua ʻelua e ke kumu kūʻai maʻalahi a me ka maʻalahi uea.ʻO ia ke ʻano maʻamau i hoʻohana ʻia i nā papa kaapuni maʻamau.

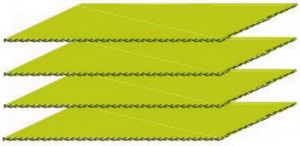

3) Pahu-papa nui

ʻO nā papa kaapuni i paʻi ʻia me nā papa ʻelua ʻoi aʻe i kapa ʻia he papa multilayer.

4) Papa HDI

ʻO ka papa HDI he papa kaapuni me ka mānoanoa mahele kaapuni kiʻekiʻe me ka hoʻohana ʻana i ka ʻenehana micro-blind buried hole.

Hoʻolālā PCB

Hoʻokumu nui ʻia ka PCB i nā laminates copper clad (Copper Clad Laminates, CCL), prepreg (PP sheet), copper foil (Copper Foil), solder mask (i ʻike ʻia he solder mask) (Solder Mask).I ka manawa like, i mea e pale ai i ka pahu keleawe i hōʻike ʻia ma luna o ka ʻili a me ka hōʻoia i ka hopena welding, pono nō hoʻi e hoʻokō i ka mālama ʻana ma luna o ka PCB, a i kekahi manawa ua hōʻailona pū ʻia me nā huapalapala.

1) Ka Lamina Copper Clad

Copper-clad laminate (CCL), i kapa ʻia he copper-clad laminate a i ʻole copper-clad laminate, ʻo ia ka mea kumu no ka hana ʻana i nā papa kaapuni paʻi.Hoʻokumu ʻia ia me kahi papa dielectric (resin, aniani fiber) a me kahi conductor maʻemaʻe kiʻekiʻe (copper foil).i haku ʻia me nā mea hoʻohuihui.

ʻAʻole hiki i ka makahiki 1960 i hoʻohana nā mea hana ʻoihana formaldehyde resin copper foil ma ke ʻano he kumu kumu no ka hana ʻana i nā PCB ʻaoʻao hoʻokahi, a hoʻokomo iā lākou i loko o ka mākeke o nā mea pāʻani moʻolelo, nā mea hoʻopaʻa leo, nā mea hoʻopaʻa wikiō, etc. Ma hope, ma muli o ka piʻi ʻana o ka pālua. -ʻaoʻao ma waena o ka puka keleawe ʻenehana hana ʻenehana, pale wela, nui Ua hoʻohana nui ʻia nā substrates epoxy paʻa i kēia manawa.I kēia mau lā, hoʻohana nui ʻia ka FR4, FR1, CEM3, nā pā seramika a me nā pā Teflon.

I kēia manawa, ʻo ka PCB hoʻohana nui ʻia i hana ʻia e ke ʻano etching, ʻo ia ke koho koho ʻana i ka papa keleawe keleawe e loaʻa ai ke ʻano kaapuni pono.Hāʻawi ka laminate copper clad i ʻekolu mau hana o ka conduction, insulation a me ke kākoʻo ma ka papa kaapuni paʻi holoʻokoʻa.ʻO ka hana, ka maikaʻi a me ke kumukūʻai hana o nā papa kaapuni i paʻi ʻia e hilinaʻi nui ʻia i nā laminates keleawe

2) Prepreg

ʻO Prepreg, i kapa ʻia ʻo PP sheet, ʻo ia kekahi o nā mea nui i ka hana ʻana o nā papa multilayer.ʻO ka nui o ka resin a me nā mea hoʻoikaika.Hoʻokaʻawale ʻia nā mea hoʻoikaika i ka lole fiber aniani (i kapa ʻia he lole aniani), kumu pepa a me nā mea hana.

ʻO ka hapa nui o nā prepregs (pepa adhesive) i hoʻohana ʻia i ka hana ʻana i nā papa kaapuni paʻi multilayer e hoʻohana i ka lole aniani i mea hoʻoikaika.ʻO ka mea pepa lahilahi i hana ʻia ma ka hoʻohuhi ʻana i ka lole aniani i mālama ʻia me ka resin glue, a laila kālua mua ʻia e ka mālama wela ua kapa ʻia ʻo prepreg.E palupalu nā prepregs ma lalo o ka wela a me ke kaomi a paʻa i ka wā e hoʻomālili ai.

No ka mea ʻokoʻa ka helu o nā kaula wili no ka lōʻihi o ka lole aniani ma ka ʻaoʻao a me ka weft, pono e nānā ʻia nā ʻaoʻao a me ka weft o ka prepreg i ka wā e ʻoki ai.ʻO ka mea maʻamau, koho ʻia ka ʻaoʻao warp (ke kuhikuhi ʻana i ka lole aniani) e like me ke kuhikuhi ʻaoʻao pōkole o ka papa hana, a ʻo ka ʻaoʻao weft ʻO ke kuhikuhi o ka ʻaoʻao lōʻihi o ka papa hana e hōʻoia i ka palahalaha o ka papa hana. papa papa a pale i ka papa hana mai ka wili a me ka deformed ma hope o ka wela.

3) Pepa keleawe

ʻO ka ʻili keleawe he ʻiʻo metala lahilahi a mau i waiho ʻia ma ka papa kumu o ka papa kaapuni.Ma ke ʻano he alakaʻi o ka PCB, hoʻopaʻa maʻalahi ia i ka papa insulating a hoʻopaʻa ʻia e hana i kahi ʻano kaapuni.

Hiki ke hoʻokaʻawale ʻia nā ʻāpana keleawe ʻenehana maʻamau i ʻelua mau ʻāpana: ʻōwili ʻia i ke keleawe keleawe (RA copper foil) a me ka electrolytic copper foil (ED copper foil):

Loaʻa ka ductility maikaʻi a me nā hiʻohiʻona ʻē aʻe, a ʻo ka foil keleawe i hoʻohana ʻia i ke kaʻina papa palupalu mua;

Loaʻa i ka Electrolytic copper foil ka maikaʻi o ke kumukūʻai hana haʻahaʻa ma mua o ka foil keleawe i ʻōwili ʻia

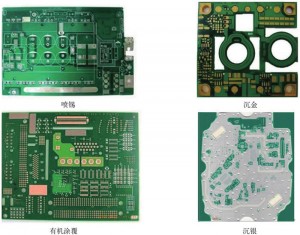

4) Māka Solder

ʻO ka papa kūʻai kūʻai e pili ana i ka ʻāpana o ka papa kaapuni i paʻi ʻia me ka inika kūʻai kūʻai.

He ʻōmaʻomaʻo maʻamau ka ʻīnika kūʻē kūʻai, a hoʻohana kekahi i ka ʻulaʻula, ʻeleʻele a me ka uliuli, a me nā mea ʻē aʻe, no laila ua kapa ʻia ʻo solder resist ink i ka ʻaila ʻōmaʻomaʻo i ka ʻoihana PCB.He papa pale mau ia o nā papa kaapuni i paʻi ʻia, hiki ke pale i ka makū, Anti-corrosion, anti-mildew a me mechanical abrasion, a me nā mea ʻē aʻe, akā e pale pū i nā ʻāpana mai ka welded i nā wahi hewa.

5) Lapaʻau ʻili

ʻO "Surface" e like me ka hoʻohana ʻia ma ʻaneʻi e pili ana i nā wahi pili ma ka PCB e hāʻawi ana i ka pilina uila ma waena o nā ʻāpana uila a i ʻole nā ʻōnaehana ʻē aʻe a me nā kaapuni ma ka PCB, e like me nā wahi hoʻopili o nā pads a i ʻole nā pilina pili.ʻOi aku ka maikaʻi o ka solderability o ke keleawe ʻole ponoʻī, akā maʻalahi ka oxidized a haumia i ka wā e ʻike ʻia ai i ka ea, no laila e uhi ʻia kahi kiʻi pale ma ka ʻili o ke keleawe ʻole.

ʻO nā kaʻina hana lapaʻau PCB maʻamau e komo pū me ke alakaʻi HASL, ke alakaʻi ʻole HASL, ka uhi kūlohelohe (Organic Solderability Preservatives, OSP), ke gula immersion, ke kala immersion, ka pahu immersion a me nā manamana gula-plated, etc. Ua pāpā ʻia ke kaʻina alakaʻi HASL.

6) Nā Kiʻi

ʻO ke ʻano o ka papa kikokikona, ma ka papa luna o ka PCB, hiki ke haʻalele ʻia, a hoʻohana maʻamau ia no nā manaʻo.

ʻO ka mea maʻamau, i mea e maʻalahi ai ka hoʻonohonoho ʻana a me ka mālama ʻana i ke kaapuni, ua paʻi ʻia nā ʻōkuhi logo a me nā code kikokikona ma ka ʻaoʻao o luna a lalo o ka papa i paʻi ʻia, e like me nā lepili ʻāpana a me nā waiwai nominal, nā ʻano kikoʻī kikoʻī a me nā logo mea hana. nā lā kali.

Paʻi pinepine ʻia nā huapalapala e ka paʻi pale

Ka manawa hoʻouna: Mar-11-2023