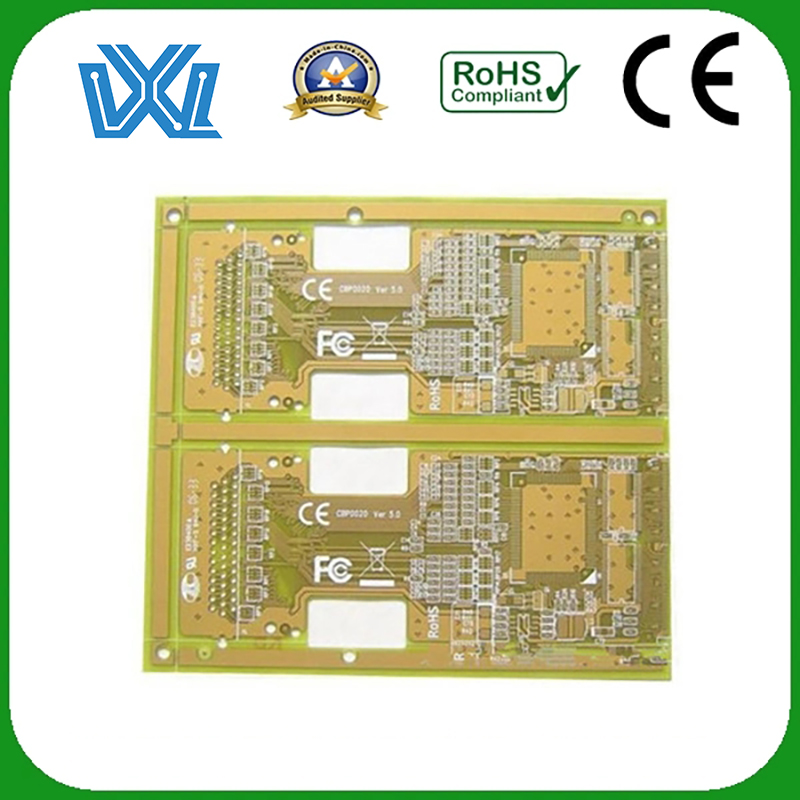

PCBA thiab PCB Board Assembly rau cov khoom siv hluav taws xob

Khoom Paub meej

| Qauv NO. | ETP-005 | Qhov xwm txheej | Tshiab |

| Min Trace Dav / Qhov Chaw | 0.075/0.075 hli | Tooj Thickness | 1-12 oz |

| Hom kev sib dhos | SMT, DIP, Los Ntawm Qhov | Daim ntawv thov teb | LED, Kev Kho Mob, Industrial, Control Board |

| Qauv khiav | Muaj | Thauj Pob | Nqus Ntim / Blister / Yas / Cartoon |

PCB (PCB Assembly) Cov txheej txheem muaj peev xwm

| Kev Xav Tau | Professional nto-mounting thiab dhau-qhov soldering Technology |

| Ntau qhov ntau thiab tsawg xws li 1206,0805,0603 Cheebtsam SMT tshuab | |

| ICT (In Circuit Test), FCT (Functional Circuit Test) tshuab | |

| PCB los ua ke nrog UL, CE, FCC, Rohs pom zoo | |

| Nitrogen roj reflow soldering tshuab rau SMT | |

| High Standard SMT & Solder Assembly Kab | |

| High density interconnected board placement technology peev xwm | |

| Quote&Production Requirement | Gerber ntaub ntawv los yog PCB ntaub ntawv rau liab qab PCB Board Fabrication |

| Bom (Bill of Material) rau Assembly, PNP (Pick thiab Place file) thiab Cheebtsam txoj haujlwm tseem xav tau hauv kev sib dhos | |

| Txhawm rau txo lub sijhawm tsocai, thov muab peb tus lej tag nrho rau txhua qhov khoom, Quantity per board kuj kom muaj nuj nqis rau kev txiav txim. | |

| Test Guide & Function Test method kom paub tseeb tias qhov zoo mus txog ze li ntawm 0% seem seem |

Cov txheej txheem tshwj xeeb ntawm PCBA

1) Cov txheej txheem ob sab kev ntws thiab tshuab.

① Cov ntaub ntawv txiav-drilling-qhov thiab tag nrho phaj electroplating- qauv hloov pauv (kev tsim zaj duab xis, raug, kev loj hlob)-etching thiab zaj duab xis tshem tawm-lub npog ntsej muag thiab cov cim-HAL lossis OSP, thiab lwm yam.-zoo li-kev tshuaj xyuas-cov khoom tiav

② Txiav cov khoom - tho - qhov - qauv hloov - electroplating - zaj duab xis stripping thiab etching - anti-corrosion zaj duab xis tshem tawm (Sn, los yog Sn / pb) - plating plug- -Solder mask thiab cim -HAL los yog OSP, thiab lwm yam. - Kev tshuaj xyuas - cov khoom tiav

(2) Cov txheej txheem ntau txheej txheej txheem txheej txheem thiab thev naus laus zis.

Cov khoom txiav-sab hauv txheej-kev kho oxidation-lamination-drilling-qhov plating (tuaj yeem muab faib ua pawg thawj coj saib thiab qauv plating)- txheej txheej ntau lawm-txheej txheej-zoo li txheej txheem-Kev tshuaj xyuas-Cov khoom tiav

(Ceeb Toom 1): Cov txheej txheej sab hauv yog hais txog cov txheej txheem ntawm cov txheej txheem txheej txheem tom qab cov khoom raug txiav - qauv hloov pauv (kev tsim zaj duab xis, raug, kev loj hlob) - etching thiab zaj duab xis tshem tawm - tshuaj xyuas, thiab lwm yam.

(Ceeb Toom 2): Txheej txheej txheej txheej yog hais txog cov txheej txheem ntawm cov phaj ua los ntawm lub qhov electroplating - txawv txav (zaj duab xis tsim, raug, kev loj hlob) - etching thiab zaj duab xis stripping.

(Ceeb Toom 3): Txheej txheej (plating) txhais tau hais tias tom qab txheej txheej yog ua-lub npog ntsej muag thiab cov cim-txheej (plating) txheej (xws li HAL, OSP, chemical Ni/Au, chemical Ag, chemical Sn, thiab lwm yam. Tos ).

(3) faus / dig muag ntawm multilayer board txheej txheem ntws thiab tshuab.

Cov txheej txheem lamination feem ntau yog siv.uas yog:

Cov ntaub ntawv txiav - tsim cov core board (sib npaug rau cov pa ob sab los yog ntau txheej board) - lamination - cov txheej txheem hauv qab no yog tib yam li cov pa ntau txheej board.

(Ceeb Toom 1): Kev tsim cov core board yog hais txog kev tsim cov txheej txheem ntau txheej nrog faus / qhov muag tsis pom kev raws li cov txheej txheem kev cai tom qab lub rooj tsav xwm ob sab lossis ntau txheej txheej yog tsim los ntawm cov txheej txheem.Yog hais tias qhov sib piv ntawm lub qhov ntawm lub core board yog loj, lub qhov thaiv kev kho yuav tsum tau nqa tawm los xyuas kom meej nws kev ntseeg tau.

(4) Cov txheej txheem ntws thiab thev naus laus zis ntawm laminated multi-layer board.

One-stop Solution

Khw Exhibition

Raws li kev pabcuam PCB kev tsim khoom thiab PCB sib dhos (PCBA) tus khub, Evertop siv zog los txhawb kev lag luam me me thoob ntiaj teb nrog kev paub txog engineering hauv Electronic Manufacturing Services (EMS) rau xyoo.