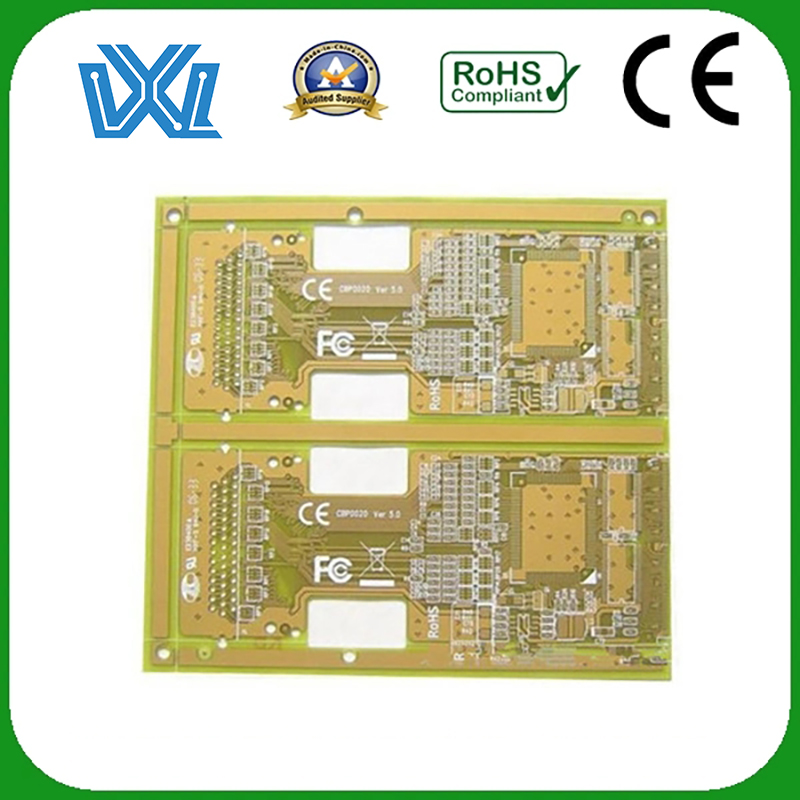

PCBA le PCB Board Assembly bakeng sa Lihlahisoa tsa Electronics

Lintlha tsa Sehlahisoa

| Mohlala NO. | ETP-005 | Boemo | E ncha |

| Min Trace Width/Space | 0.075/0.075mm | Botenya ba Koporo | 1 - 12 Oz |

| Mekhoa ea Kopano | SMT, DIP, Ka Hole | Sebaka sa Kopo | LED, Medical, Industrial, Control Board |

| Mehlala ea matha | E fumaneha | Sephutheloana sa Lipalangoang | Vacuum Packing/Blister/Plastiki/Cartoon |

PCB (PCB Assembly) Bokhoni ba Ts'ebetso

| Tlhokahalo ea Theknoloji | Professional Surface-mounting and Through-hole soldering Technology |

| Mefuta e fapaneng e kang 1206,0805,0603 likarolo tsa theknoloji ea SMT | |

| Teko ea ICT(Tekong ea Potoloho), tekhenoloji ea FCT(Teko e sebetsang ea potoloho). | |

| Kopano ea PCB Ka UL, CE, FCC, Tumello ea Rohs | |

| Theknoloji ea ho hlahisa khase ea naetrojene bakeng sa SMT | |

| High Standard SMT&Solder Assembly Line | |

| Matla a thekenoloji a ho beoa ha boto a phahameng a hokahaneng | |

| Quote & Tlhokahalo ea Tlhahiso | Gerber File kapa PCB File bakeng sa Bare PCB Board Fabrication |

| Bom(Bill of Material) bakeng sa Kopano,PNP(Faele ea Khetha le Sebaka) le Boemo ba likarolo le tsona lia hlokahala kopanong. | |

| Ho fokotsa nako ea quote, ka kopo re fe nomoro ea karolo e felletseng bakeng sa karolo ka 'ngoe,Bongata ka boto le palo ea liodara. | |

| Tataiso ea Teko le Mokhoa oa Teko oa Mosebetsi ho etsa bonnete ba hore boleng bo fihla ho sekhahla sa sekhechana sa 0%. |

Mokhoa o khethehileng oa PCBA

1) Phallo e tloaelehileng ea mahlakore a mabeli le theknoloji.

① Ho itšeha - ho phunya - lesoba le poleiti e felletseng ea electroplating - phetisetso ea mohlala (sebopeho sa filimi, ho pepeseha, nts'etsopele) - etching le ho tlosoa ha filimi - mask le litlhaku tse rekisoang - HAL kapa OSP, joalo-joalo.

② Ho khaola thepa-ho phunya-holeization-mohlala oa phetisetso-electroplating-ho hlobolisa filimi le etching-ho tlosoa ha filimi e thibelang ho bola (Sn, kapa Sn/pb)-plating plug- -Solder mask le litlhaku-HAL kapa OSP, joalo-joalo. -tlhahlobo-sehlahisoa se felileng

(2) Mokhoa o tloaelehileng oa boto ea mekhahlelo e mengata le theknoloji.

Lintho tse sehang - ka hare lera tlhahiso - oxidation kalafo - lamination - ho cheka - lesoba plating (e ka aroloa ka boto e feletseng le paterone plating) - bokantle lera tlhahiso - holim'a barbotage - Shape sebetsa - Inspection - Finished sehlahisoa

(Tlhokomeliso 1): Tlhahiso ea lera e ka hare e bolela ts'ebetso ea boto ea ts'ebetso ka mor'a hore thepa e khaotsoe-ho fetisoa ha mohlala (sebopeho sa filimi, ho pepeseha, nts'etsopele) -etching le ho tlosoa filimi - tlhahlobo, joalo-joalo.

(Tlhokomeliso 2): Ho etsoa ha lesela la ka ntle ho bolela mokhoa oa ho etsa lipoleiti ka lesoba la electroplating-pattern transfer (sebopeho sa filimi, ho pepeseha, nts'etsopele) -etching le ho hlobola filimi.

(Tlhokomeliso 3): Ho roala ka holim'a sefahleho (plating) ho bolela hore ka mor'a hore ho etsoe lesela la ka ntle-mask ea solder le litlhaku-coating (plating) layer (e kang HAL, OSP, lik'hemik'hale tsa Ni / Au, lik'hemik'hale Ag, lik'hemik'hale Sn, joalo-joalo Ema. ).

(3) Ho patoa / ho foufala ka ho phalla ha multilayer board le theknoloji.

Ka kakaretso ho sebelisoa mekhoa ea sequential lamination.e leng:

Lisebelisoa tsa ho itšeha-ho etsa boto ea mantlha (e lekanang le boto e tloaelehileng ea mahlakoreng a mabeli kapa e mengata) -lamination-ts'ebetso e latelang e tšoana le boto e tloaelehileng ea marako a mangata.

(Tlhokomeliso ea 1): Ho theha boto ea mantlha ho bolela ho thehoa ha boto ea lihlopha tse ngata tse nang le masoba a patiloeng / a foufetseng ho ea ka litlhoko tsa moralo ka mor'a hore boto e nang le mahlakoreng a mabeli kapa e mengata e thehoe ka mekhoa e tloaelehileng.Haeba karolo ea karolo ea lesoba la boto ea mantlha e le khōlō, phekolo ea ho thibela sekoti e lokela ho etsoa ho netefatsa hore e tšepahala.

(4) Phallo ea ts'ebetso le theknoloji ea boto ea laminated multi-layer board.

One-stop Tharollo

Pontšo ea mabenkele

Joaloka molekane ea etellang pele litšebeletso tsa PCB le kopano ea PCB (PCBA), Evertop e ikitlaelletsa ho tšehetsa khoebo e nyenyane ea machaba e nang le phihlelo ea boenjiniere ho Electronic Manufacturing Services (EMS) ka lilemo.