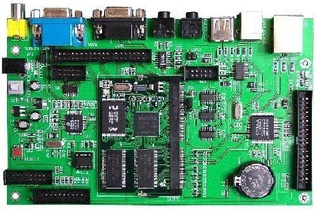

Inkqubo ye-PCBA: PCBA=INdibano yeBhodi yeSekethe eprintiweyo, oko kukuthi, ibhodi ye-PCB engenanto idlula inxalenye ephezulu ye-SMT, kwaye idlule kuyo yonke inkqubo ye-DIP plug-in, ebizwa ngokuba yinkqubo ye-PCBA.

Inkqubo kunye neTekhnoloji

Jigsaw ukujoyina:

1. Uxhulumaniso lwe-V-CUT: usebenzisa i-splitter ukwahlula, le ndlela yokwahlula ine-smooth cross-section kwaye ayinayo imiphumo emibi kwiinkqubo ezilandelayo.

2. Sebenzisa i-pinhole (umngxuma wesitampu) uxhulumaniso: Kuyimfuneko ukuqwalasela i-burr emva kokuphuka, kwaye ingaba iya kuchaphazela ukusebenza okuzinzile kokulungiswa kumatshini we-Bonding kwinkqubo ye-COB.Kufuneka kwakhona kuqwalaselwe ukuba kuya kuchaphazela iplagi-in track kunye nokuba iya kuchaphazela ibandla.

Izinto zePCB:

1. IiPCB zekhadibhodi ezifana ne-XXXP, FR2, kunye ne-FR3 zichaphazeleka kakhulu ngubushushu.Ngenxa yokwandiswa kwe-thermal coefficients, kulula ukubangela ukudumba, ukuguqulwa, ukuphuka, kunye nokuchithwa kwesikhumba sobhedu kwi-PCB.

2. Ii-PCB zebhodi ze-Glass ze-Glass ezifana ne-G10, i-G11, i-FR4, kunye ne-FR5 azichatshazelwa kangako ngubushushu be-SMT kunye nobushushu be-COB kunye ne-THT.

Ukuba ngaphezulu kwe-COB ezimbini.SMT.Iinkqubo zokuvelisa i-THT ziyafuneka kwi-PCB enye, ngokuqwalasela zombini umgangatho kunye neendleko, i-FR4 ifanelekile kwiimveliso ezininzi.

Impembelelo yocingo lwentambo yoqhagamshelo lwepadi kunye nendawo yokuphumela komngxuma kwimveliso ye-SMT:

I-wiring yemigca yokuqhagamshelwa kwe-pad kunye nokuma kwemingxuma kunempembelelo enkulu kwimveliso ye-soldering ye-SMT, kuba imigca yokudibanisa i-pad engafanelekanga kunye nemingxuma inokudlala indima "yokweba" i-solder, ukufunxa i-solder yolwelo kwi-oven reflow Go. i-siphon kunye ne-capillary action in fluid).Ezi meko zilandelayo zilungele umgangatho wemveliso:

1. Nciphisa ububanzi bomgca woqhagamshelo lwepadi:

Ukuba akukho mda wokuthwala umthamo wangoku kunye nobukhulu bokuvelisa i-PCB, ububanzi obukhulu bomgca wokudibanisa i-pad yi-0.4mm okanye i-1/2 pad ububanzi, obunokuba buncinci.

2. Kukhethwa kakhulu ukusebenzisa imigca yoqhagamshelo emxinwa enobude obungekho ngaphantsi kwe-0.5mm (ububanzi bungabi ngaphezu kwe-0.4mm okanye ububanzi obungekho ngaphezu kwe-1/2 yobubanzi bepadi) phakathi kweepads eziqhagamshelwe kwimicu ye-conductive yendawo enkulu ( njengeenqwelomoya eziphantsi komhlaba, iinqwelomoya zamandla).

3. Gwema ukudibanisa iingcingo ukusuka kwicala okanye kwikona kwi-pad.Okungcono kakhulu, ucingo lokudibanisa lungena lusuka phakathi ngasemva kwepadi.

4. Ngemingxuma kufuneka kuphetshwe kangangoko kunokwenzeka kwiipads zamacandelo e-SMT okanye kufuphi ngqo neepads.

Isizathu kukuba: umngxuma ophumela kwiphedi uya kutsala i-solder emngxunyeni kwaye wenze i-solder ishiye i-solder joint;umngxuma usondele ngqo kwi-pad, nokuba kukho ukhuseleko olulungileyo lweoyile eluhlaza (kwimveliso eyiyo, ushicilelo lweoyile eluhlaza kwi-PCB yezinto ezingenayo ayichanekanga kwiimeko ezininzi), kunokubangela ukutshisa ubushushu, okuya kutshintsha isantya sokungena kwi-solder joints, kubangela ukuba i-tombstoneing isenze kumacandelo e-chip, kwaye ithintele ukubunjwa okuqhelekileyo kwamalungu e-solder kwiimeko ezinzima.

Uqhagamshelo phakathi komngxuma odlulayo kunye nephedi yeyona nto ikhethwayo ngumgca woqhagamshelo olumxinwa onobude obungekho ngaphantsi kwe-0.5mm (ububanzi bungekho ngaphezulu kwe-0.4mm okanye ububanzi obungekho ngaphezulu kwe-1/2 yobubanzi bepadi).

Ixesha lokuposa: Feb-22-2023